Auke Visser´s ESSO Tankvaart Mij. Site | home

Tekening van een Schotse Ketel / Drawing of a Scotch Boiler

Source : Lars Josefsson

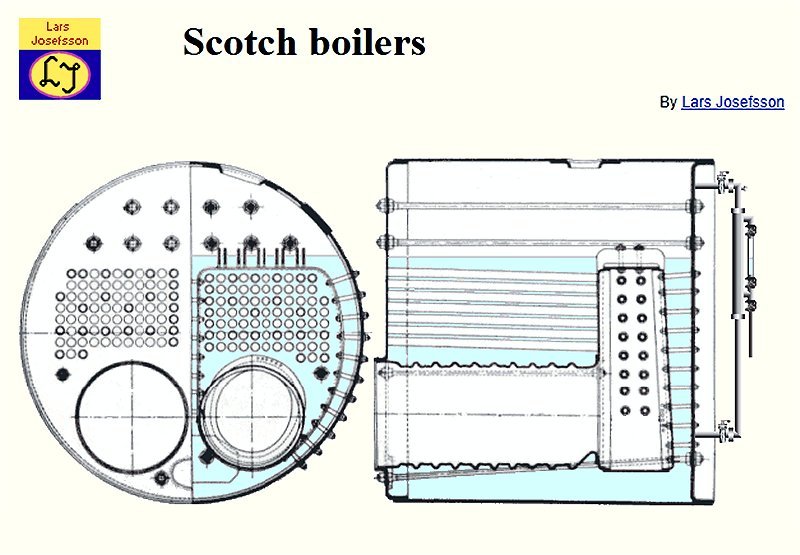

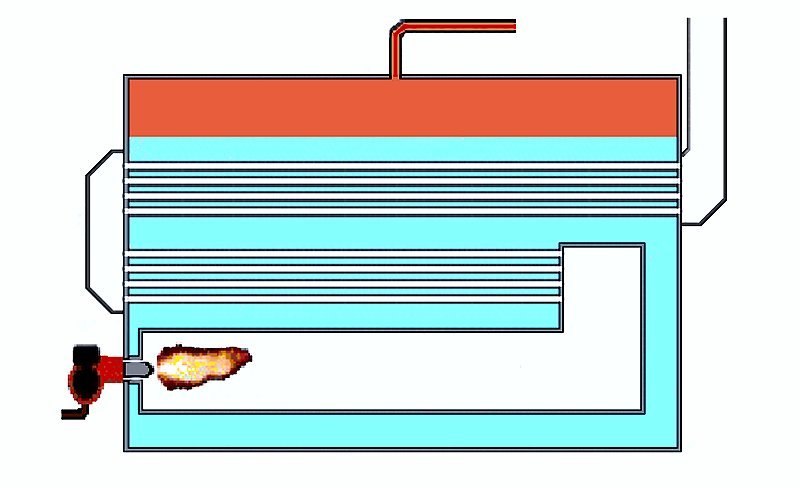

Drawing of a Scotch Boiler.

The single-ended return tube Scotch boiler consists of a cylindrical boiler shell of large diameter and short length,

provided with two or more furnaces i.e. corrugated fire-tubes. Each furnace ends in a combustion chamber,

surrounded by water. The gases pass through a bank of flue-tubes from the combustion chamber to the smoke-box

at the boiler front.

( Copyright Lars Josefsson )

A Scotch boiler contained large quantity of water, about six times more than a water-tube boiler, and was therefore slow

to steam up and to change the output capacity. Due to the Scotch boiler's stiff construction it required also a long

steaming up period to avoid leaks caused by thermal expansion of the material.

The Scotch boiler was a very common marine boiler, used in steamships from many nations.

( Copyright Lars Josefsson )

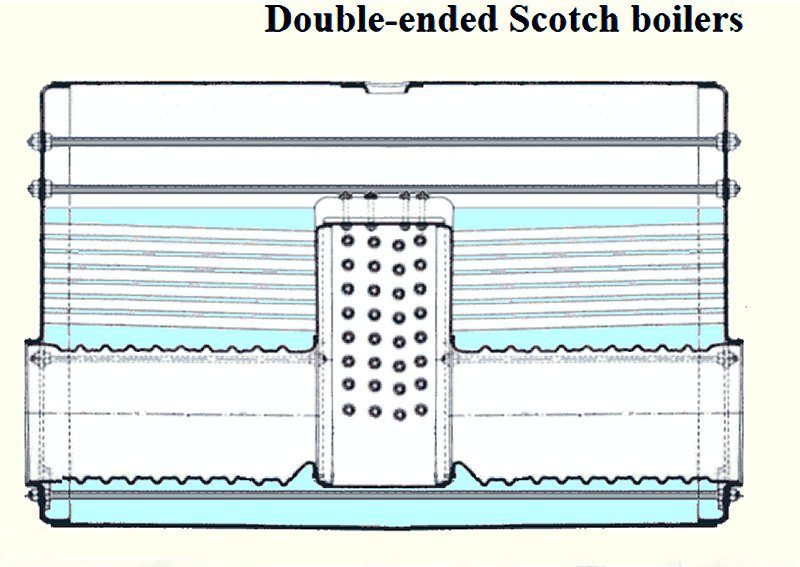

Double-ended Scotch boiler.

These types of boilers were normally used in ships with many Scotch boilers. Space was saved even though two stokeholes

were required. Normally a pair of furnaces shared one combustion chamber.

In older double-ended boilers were often vertical Galloway tubes built into the combustion chamber. They were intended to

promote water circulation in the boiler and thus contribute to reducing tensions in the material.

Twenty-four double-ended Scotch boilers with three furnaces at each end and five single-ended Scotch boilers with three furnaces

were installed onboard R.M.S. Titanic. Electrically operated stoking indicators were used in the stokeholds to prevent that opposite

furnace doors were open at the same time. These indicators also helped to minimize the total number of simultaneously open boiler

furnace doors.

( Copyright Lars Josefsson )

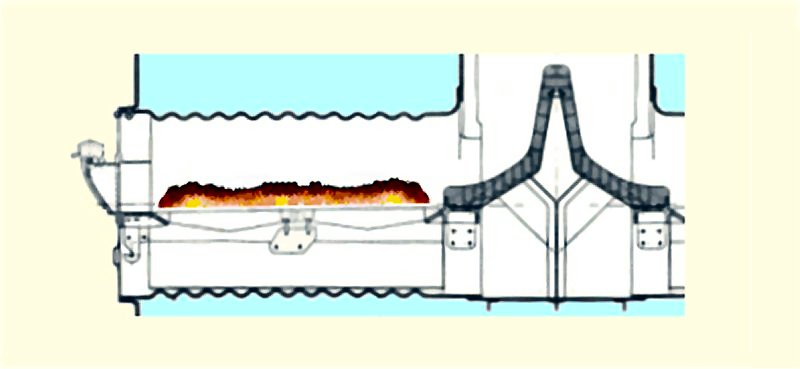

When the furnace door was open, cold air could hit the combustion chamber's opposite wall and cause tube leakage. To prevent that,

a high baffle of firebrick was installed in the middle of the combustion chamber.

( Copyright Lars Josefsson )

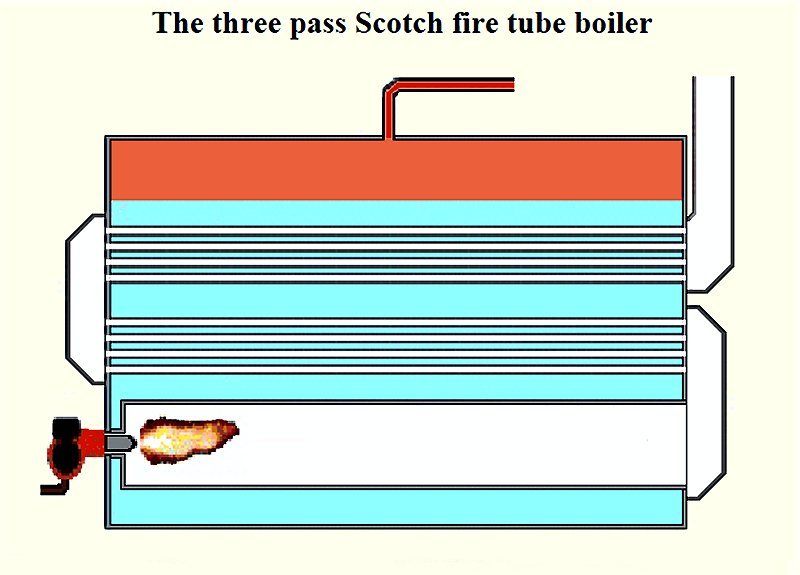

The three pass Scotch fire tube boiler.

The flue gases passes three times through the water space in stead of two times that was common in the old Scotch boilers. It is a further

development of the Scotch fire tube boiler, often referred to as the Scotch boiler.

( Copyright Lars Josefsson )

The three pass Scotch fire tube boiler.

( Copyright Lars Josefsson )