Auke Visser's International Esso Tankers site | home

Newport News Ships Bulletin "Esso Houston" - Part-2

Source: Shipyard Bulletin, Newport News Shipbuilding and Dry Dock Company. (Volume XXIV - Number 8, December,1964)

The galley of the ESSO HOUSTON is equipped with the latest stainless steel electric stoves and ovans and other facilities.

Many small details have also been planned with an emphasis on safety. Anchor pawls are counter- weighted so that one man can move them without strain. Non-skid paint covers exposed outer decks.

The use of protective coatings played a major role in the construction of the ESSO HOUSTON. By protecting steel against corrosion, the coatings are designed to prolong the life of the vessel and to reduce upkeep and maintenance costs. Coatings were

applied to the surfaces of the tank interiors and to interior and exterior surfaces of vent and cargo piping.

It marked the first time that coatings have been used so extensively during the construction of a Humble tanker.

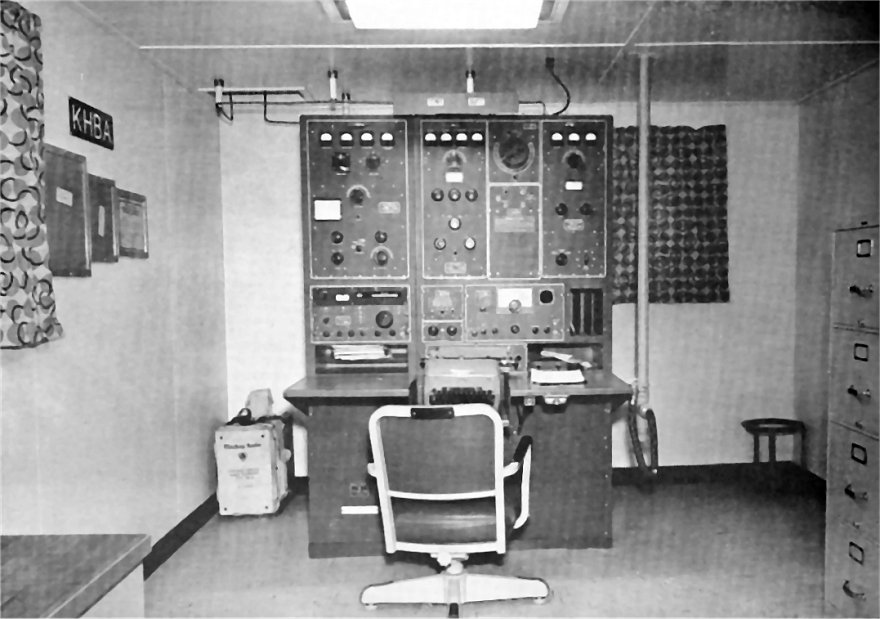

The radio room on the ESSO HOUSTON includes the latest electronic equipment for communication between sea and land.

The ESSO HOUSTON's cargo space is longer than two city blocks. The 21 tanks hold 582,856 barrels.

The cargo pumping equipment consists of four 7,000 gallons-per-minute turbine-driven deep well pumps for petroleum and two 1,400 gallons-per-minute turbine-driven deep well pumps for special cargoes.

Ballasting of main cargo tanks is accomplished through a single fore and aft main raking suction from a sea chest forward and another sea chest aft.

Ballast is pumped by main deep well cargo pumps. The same fore and aft line serves the main cargo system.

A completely separate ballast system permits ballasting and deballasting while discharging and loading with no risk of product contamination or oil pollution of harbor waters.

As cargo is loaded, gases are dispelled through a series of vent pipes exhausting directly to the atmosphere. Similarly, when cargo is discharged, air is admitted through the vent pipes to take the place of the liquid. Flame artesters are installed at the topmost point ofthe vent lines.

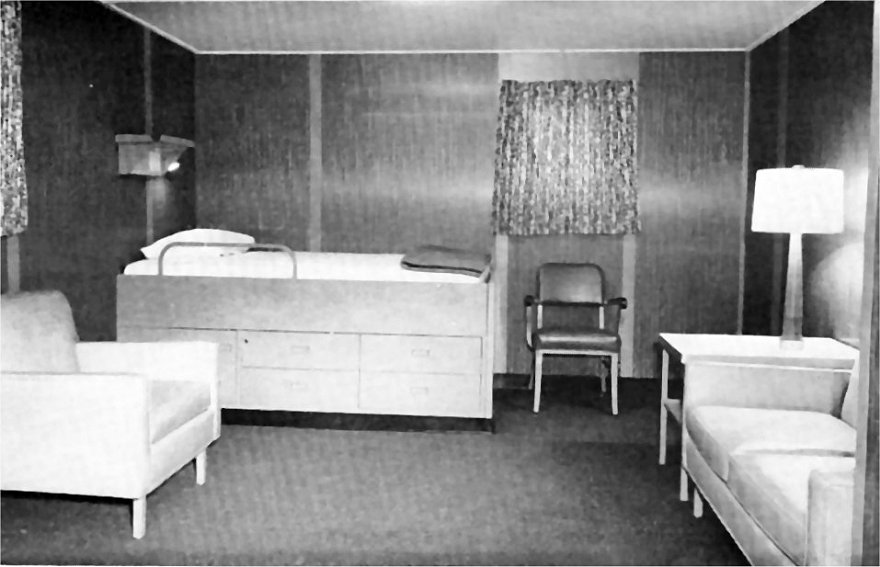

The stateroom of the Chief Engineer has moss green carpats wilh bulkheads ol simulated wood paneling. The chairs are shades of gold and green.

Since cargo is pumped at such a rapid rate, an emergency stopping system is very important. Three remote control stations are provided which can shut off the steam to the cargo pump turbines and stop all pumping in less than a minute.

Each tank is fitted with a modern float gauge to provide oil level measurements while the tanks are closed. With this equipment, all loading and unloading operations can be carried on without opening rhe tanks and allowing dangerous vapors to accumulate

on deck.

With these modern facilities, the ESSO HOUSTON is able to arrive at a port, load or discharge 66,700 tons of petroleum cargo in a safe and efficient manner and leave — in less than one day.

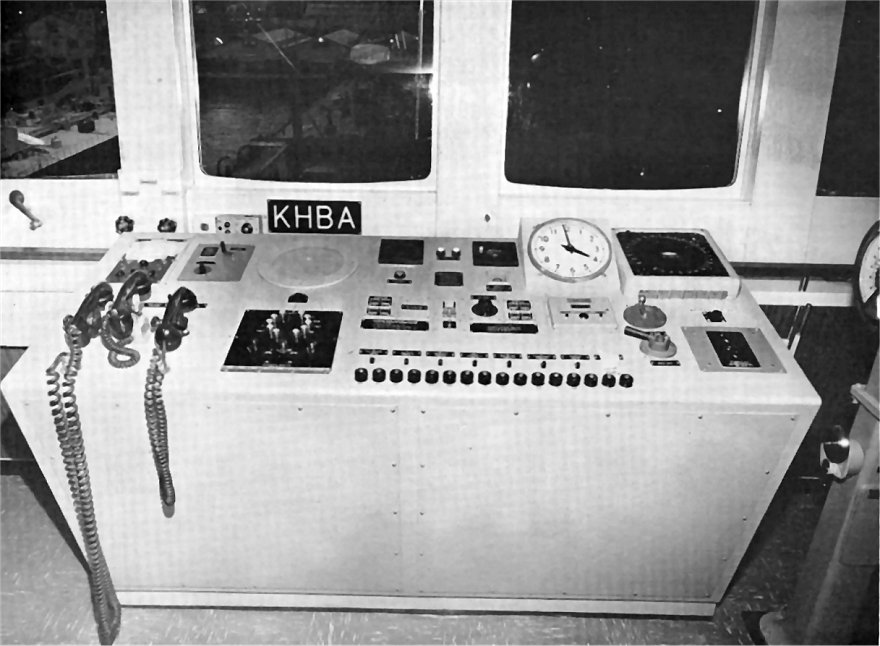

Close-up view of the automated console controls of the ESSO HOUSTON on the navigation bridge.

( Thanks to S. Dale Hargrave )

|