Auke Visser's International Esso Tankers site | home

ESSO SUEZ LAUNCHED

Source : Shipyard Bulletin, publication by Newport News Shipbuilding and Dry Dock Company.

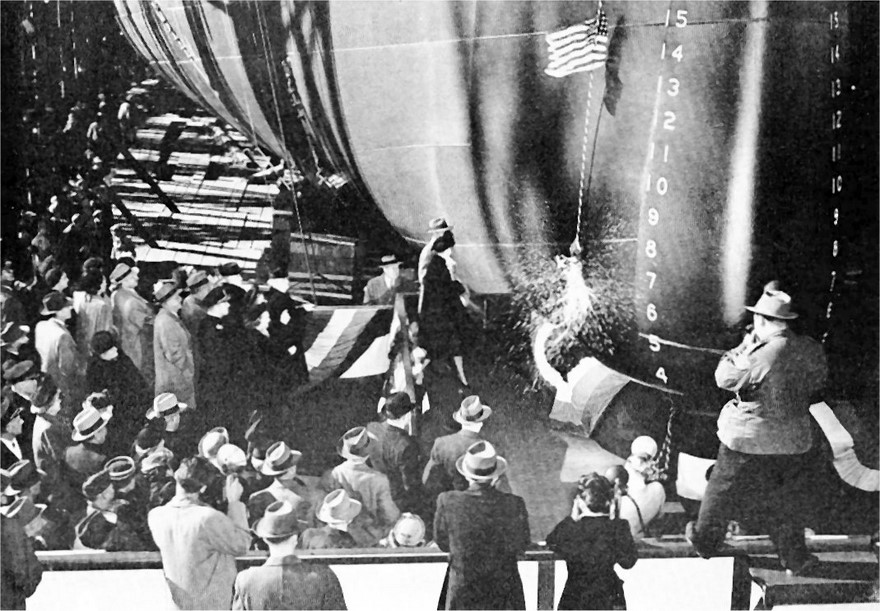

ESSO SUEZ is christened by Mrs. F. H. Bedford Jr., on January 14, 1949.

The Essa Suez, first of ten tankers we are building for the Standard Oil Company (New Jersey), was launched from Shipway Nine at 11:30 A.M. January 14, 1949. If all the voyages of the Esso Suez follow the successful pattern made when she was launched, the vessel will enjoy a career of smooth sailing. Mrs. Frederick H. Bedford, Jr., wife of a director of the Owners and Sponsor of the ship, performed her bottle-smashing duties effectively and vigorously.

The first vessel of this class of 628-foot tankers, the Esso Zurich, was launched at Sun Shipbuilding and Dry Dock Company on December 4, 1948. Mrs. Frank W. Abrams, wife of the Chairman of the Board of the Owners and Sponsor for that ship, was present to witness Mrs. Bedford’s faultless christening technique.

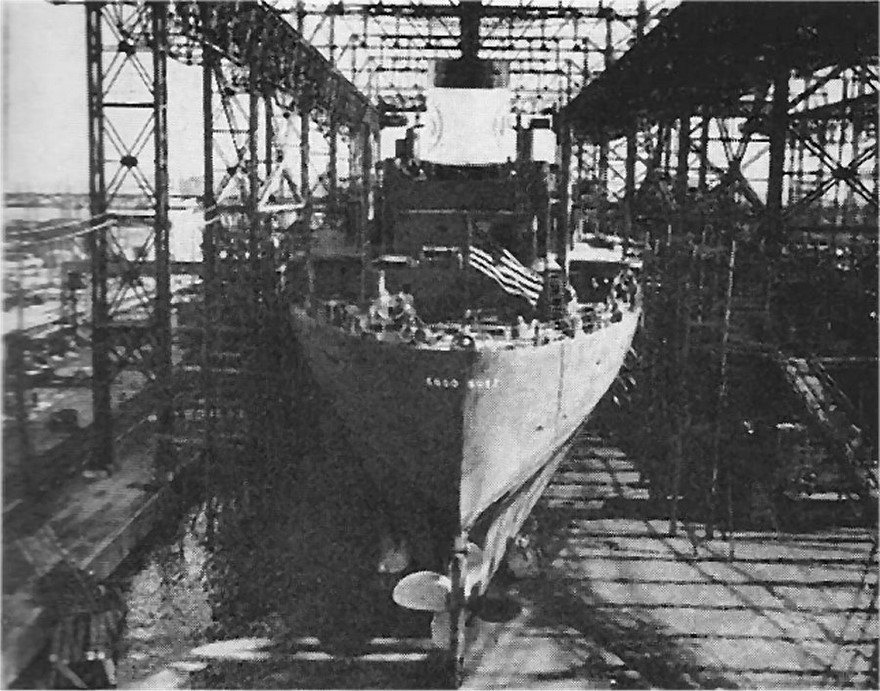

Sfern view of ESSO SUEZ after water had been permitted to enter shipway No. 9 on morning of launching.

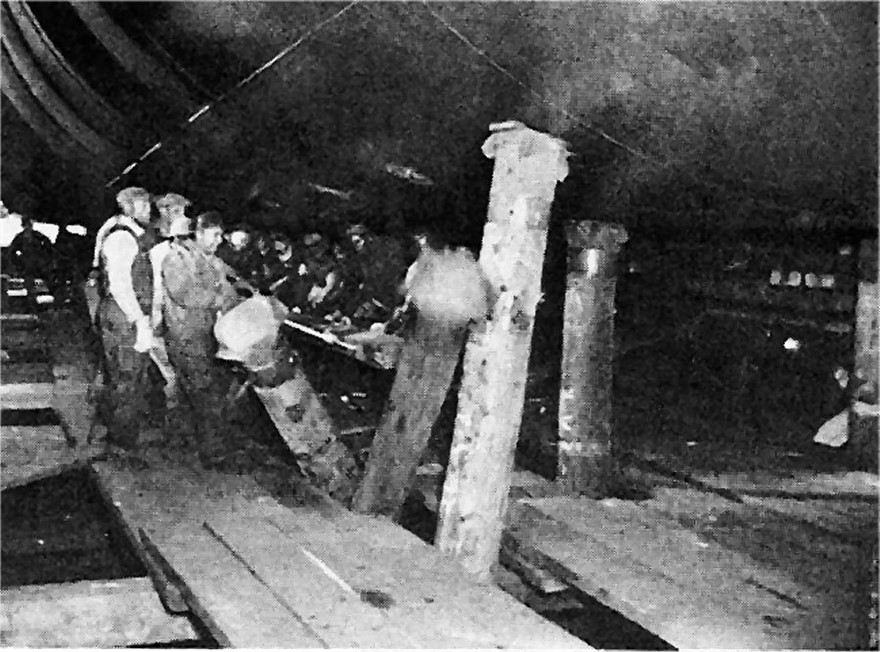

Launching operations for the Esso Suez began at 7:00 A. M. with the removal of the grease irons. By eight-thirty all of the cribbing and shores below the high-water mark had been removed and hauled clear.

Valves for flooding the shipways were opened at eight-fifteen, and by ten-forty-five both shipway gates had been removed. Other removal operations proceeded according to schedule, and the vessel started on her slide down the ways at the appointed time of 11:30 A.M. when the triggers were released.

Removing shores underneath ESSO SUEZ

This was the first sliding launching in our Yard since the Metapan of the United Fruit Company was launched from Shipway Two on November 26, 1946. The last previous launching to be made from Shipway Nine was The Emex-class carrier Leyte on August 23, 1945. There has been other activity in Shipway Nine, however, for it was there the bow section of Nueva Andalusia was floated on December 27, 1946, the only half~ship ever constructed in our Yard.

Sponsor and group of distinguished guests at launching of ESSO SUEZ.

Left to right: B.B. Howard, a director of Standard Oil Co. (New Jersey) and Mrs. Howard, F.H. Bedford, jr., a director of Standard Oil Co. (New Jersey), Mrs. William L. Stewart, mother of the sponsor, J.B. Woodward, Jr., President and General Manager of our Company, Mrs. F.H. Bedford, Jr., the sponsor, Mrs. Frank W. Abrams, wife of the Chairman of Board, Standard Oil Co. (New Jersey) and sponsor of the ESSO ZURICH, launched at Sun Shipbuilding and Dry Dock Co. on December 4, 1948 and M.G. Gamble General Manager Marine Department, Standard Oil Co. (New Jersey).

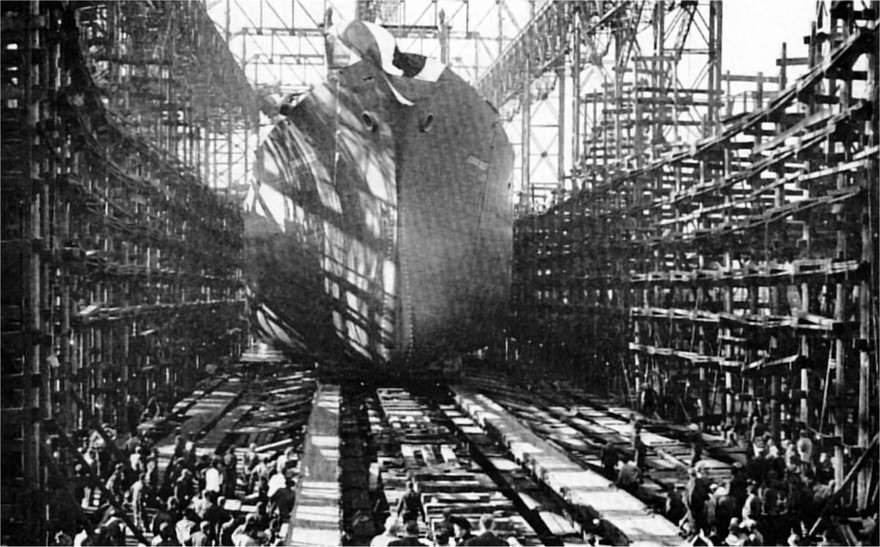

ESSO SUEZ Launch.

The Esso Suez and her thirteen sister ships were designed jointly by the Sun Shipbuilding and Dry Dock Company and the Standard Oil Company (New Jersey) Marine Department. The hull is of the single~deck type with two longitudinal bulkheads throughout the cargo tanks, which are subdivided into a total of thirty compartments and are separated from the end compartments by cofferdams or pump rooms. Forecastle and poop superstructure and amidship deck houses are fitted. Quarters are provided for a total complement of sixty~two persons including spares. Deck and engineering officers are housed amidship, while messrooms, recreation rooms, crew’s quarters, and petty ofiicers’ quarters are aft.

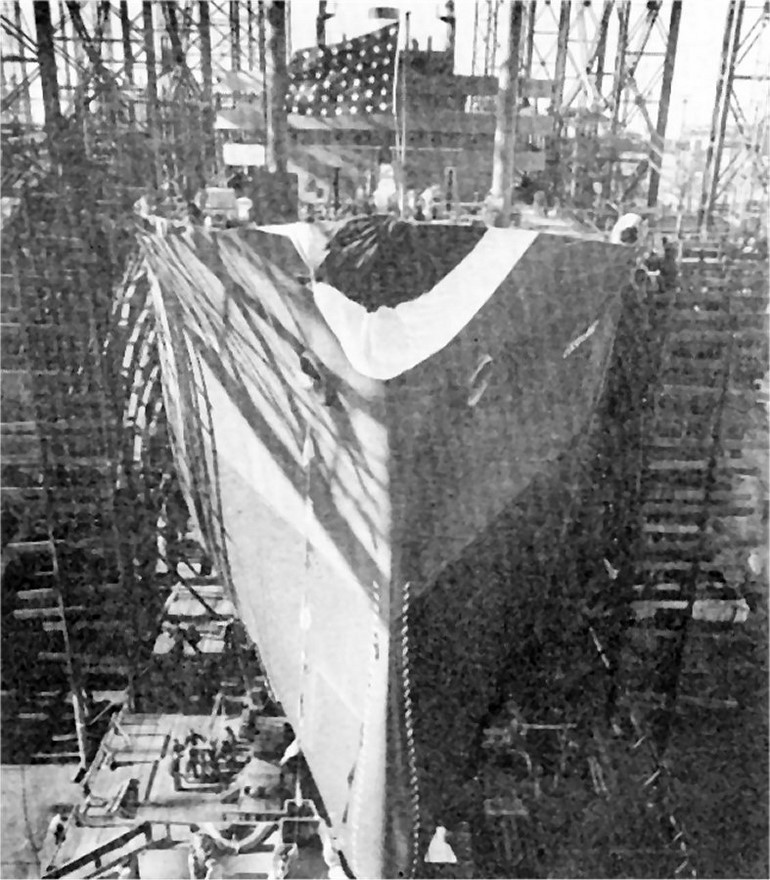

Bow view of the ESSO SUEZ taken on the morning of the launching.

Steel Hull Construction

On the date of being awarded the contract for construction of the Standard Oil Company (New Jersey) tankers our Steel Hull Division began to plan in detail the most desirable and economical procedures and methods for building these similar vessels.

An inboard profile of the ship was drawn and marked off into sections. These sections were numbered consecutively from one to twenty-four in the order of their erection sequence for building the hull. Section One was aft of midship in way of Number Eight cargo oil tank. Erection was started at this point in order to have the machinery spaces erected, fitted, welded and tested to allow ample time within the building period for installation of the main propelling machinery and auxiliaries.

With the use of the erection sequence an overall master schedule of working procedure was developed and dates were assigned for completion of all building operations in each section, including steel, outfitting and machinery work. Schedule dates were assigned for all details of construction, material, plans, molds, lay-off, fabrication, subassembly, erection, fitting, riveting, welding, searching, and testing.

Ample crane capacities are available and large assemblies up to 100 long tons were planned in units to take full advantage of automatic machine and “down hand” welding. In the bottom assemblies a considerable amount of piping with all possible joints made up and welded were installed in the assemblies before erection on the ships.

Assemblies in the cargo tanks ranged from forty to sixty tons each. The bow was assembled in two complete units; the stern in three sections, each with assemblies up to 100 tons. In the forward and after sections of the vessel, where the lines change from

parallel middle body to considerable shape, a series of jigs were constructed for repetitive construction of assemblies for all eleven vessels.

Approximately 6,000 long tons of steel were used in building the vessels along with about 150,000 pounds of weld metal and 40,000 rivets. At the time of launching the Esso Suez was ninety-five percent structurally complete. All testing had been completed, and the outfitting work was well ahead of schedule, even to having the life boats in place.

ESSO SUEZ floats in the water of the James River for lhe first time.

Machinery

The propulsion machinery, consisting of high-speed, cross-compound steam turbines, is arranged aft. It drives, by means of double reduction gearing, a twenty-foot diameter, single, solid propeller at a normal 112 revolutions per minute. Steam is generated in two

2-drum-type watertube boilers at 850 pounds per square inch gauge pressure and 850 degrees Fahrenheit temperature. The boilers are fitted with superheaters, economizers, desuperheaters, and air heaters.

Two 400-kilowatt, steam-turbine-driven generators and one 60-kilowatt, diesel-driven emergency generator supply three-phase alternating current at 450 volts and cycles.

The steering gear is of the ram type, operated by electric-hydraulic means, while windlass and deck winches are steam driven.

Tanker Capacities

Bulk transport by water is the most economical method of moving oil long distances. That is one reason why the world’s tanker fleets have grown steadily until they now total approximately twenty-one million tons of cargo-carrying capacity. More than a third of

this total was accounted for by the T-2’s of the United States Maritime Cnmmissi0n’s wartime building program.

( Thanks to S. Dale Hargrave )

|