Auke Visser's International Esso Tankers site | home

MV Esso Pelham & Barge Esso Tow No. 1 (1958 - ?? )

A NEW SHALLOW DRAFT TRANSPORTATION UNIT.

In september 1960 Humble Oil & Reflning Company put into operation the MV Esso Pelham and barge Esso Tow No. 1. They were conceived in 1958 as the solution to difficulties encountered in the supply of several terminals located on restricted tidal waterways in the New York/New England area. The main points to be served were terminals located at Pelham, Brooklyn, Oceanside and Idle-wild Airport in New York; Hackensack and Newark, New Jersey; and Byram, Connecticut. The distances to these points range about 10 to 45 statute miles from the New Jersey refineries, which are the source of supply. The service required a unit having good seakeeping properties for the bay, sound, and short coastwise operations. Furthermore, a high degree of maneuverability was essential to cope with a combination of tidal currents, heavy traffic congestion, tortuous channels and limited available depths of water in the creeks.

After preliminary study, a model tank-testing program was carried out to develop the lines and other characteristics

required of equipment for this service. Final construction plans were then prepared. These units, as they now exist,

embody features of Mississippi River type push-towing design coupled with those required for hawser-towing in rough water. The tow represents Humble's current concept of the ideal type of equipment for transportation of bulk oil in such services.

|

Towboat MV ESSO PELHAM

|

|

Length Overall

|

85 ft;, 7 in. (26.1 rh)

|

Depth at Side

|

9 ft., 4 in. (2.8 m)

|

Draft

|

7 ft., 0 in. (2.1 m)

|

Beam Moulded

|

26 ft., 3 in. (8.0 m)

|

Height-Keel to Mast Top

|

33 ft., 0 in. (10.1 m)

|

Design Speed (Under Load)

|

10.25 knots (19 km/hr)

|

Propulsion Units (2)

|

Fairbanks-Morse (Diesel)

|

Brake Horsepower (Combined)

|

1,280 BHP

|

Diameter of Propellers (2)

|

Feet 6 inches. (2.0 m)

|

Barge ESSO TOW NO. 1

|

|

Length Overall

|

190 ft., 0 in. (57.9 m)

|

Depth at Side

|

15ft., 6 in. (4.7m)

|

Draft

|

12 ft., 6 in. (3.8 re)

|

Beam Moulded

|

38 ft., 0 in. (11.5 m)

|

Height-Keel to Mast Top

|

33ft., 0 in. (10.1 m)

|

Design Deadweight

|

1,830 long tons

|

Cubic Capacity

|

(1,859 met. tons) 17,100 barels (2,719 cu. m)

|

No. of Cargo Tanks

|

4

|

No. of Cargo Compartments

|

8

|

Cargo Pumping Engines (2)

|

GM 6-110 (260 HP diesel)

|

Cargo Pumps (2)

|

Bingham deep-well

|

Rated Pump Capacity (Combined)

|

6,500 barrels per hour (1,033 cu.m/hr)

|

The twin-screw towboat, of welded steel-hull construction and diesel powered, was built by Southern Shipbuilding Corporation at Slidell, Louisiana. Because of limited available water depth and the need for good propulsive characteristics, the towboat has a modified tunnel-transom stern and operates at a 7 to 7 1/2 ft.-draft. The all-welded steel barge was built by Nashville Bridge Company, Nashville, Tennessee. The two units are designed for push-, alongside-, and hawser-towing.

The towboat is driven by two four-bladed stainless steel propellers through reverse-reduction gears having a ratio of 5:1. Design speed is reached when the propellers are turning at the rate of 233 revolutions per minute with the engines developing 1,280 BHP while pushing the cargo unit loaded to a draft of 12 1/2 feet. Kort nozzles around the propellers increase thrust and efficiency. Double sets of steering and flanking rudders are provided and are actuat-ed by an electro-hydraulic system permitting a high degree of control and maneuverability. The diesel propulsion engines are of the vertical opposed-piston type.

The towboat is equipped with the usual navigational equipment, including radar, VHF radio, and gyro and magnetic compasses. An air winch, remotely controlled from the pilothouse, saves manual hauling of the wire towing cables between the towboat and barge. The main propulsion engines are also controlled from the pilothouse. The tow-boat is designed also to take the barge on a hawser when wave conditions prohibit pushing.

The barge has a spoon-bow designed to minimize water resistance. Variable-fin, "flow-line" skegs. at the stern create minimum resistance when the barge is being pushed, yet provide directional stability when being towed on a hawser.

The fins are trimmed by hand-operated wheels located on deck. The stem is notched to accommodate the bow of the towboat when push-towing. The barge is designed for minimum obstruction to visibility and may also be pushed stern foremost. When in light condition, this permits prompt departures without having to turn in narrow channels.

|

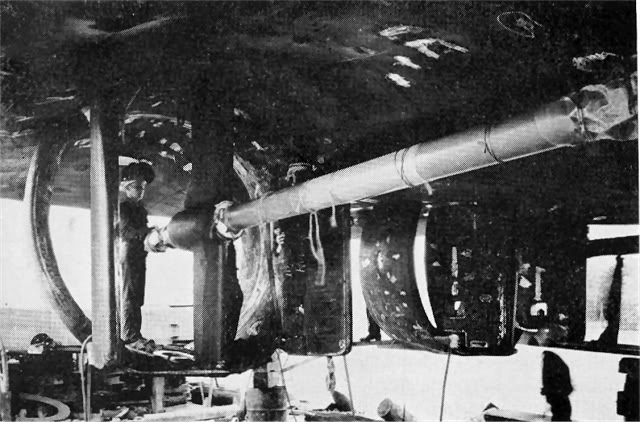

Above - Kort nozzles, propeller shafts and flanking rudders are clearlyvisible during construction

of the ESSO PELHAM.

Interior of pilothouse showing arrangement of engine and rudder controls and aids to navigation.

Separate hydraulic stripping pumps facilitate drainage of the cargo system. Provision has been made for shutting down the cargo pumping engines from remote locations should an emergency arise during discharge. Pumping engines are located away from the cargo hose connections. Hose handling gear and the anchor windlass are operated hydraulically. The anchor is self-stowing.

An interesting feature during the construction of the barge was the coating of interior cargo tank sections with an anti-corrosion inorganic zinc compound at the sub-assembly stage. This avoided many of the problems encountered in the application of such coatings in closed spaces after completion of construction. The outcome was a better coating at less cost.

The end result is a unit which can operate and handle cargo expeditiously, even under unfavorable conditions.

|

Above - View on deck of the Esso Barge No. 1 showing part of the cargo system, pump engines and drives.

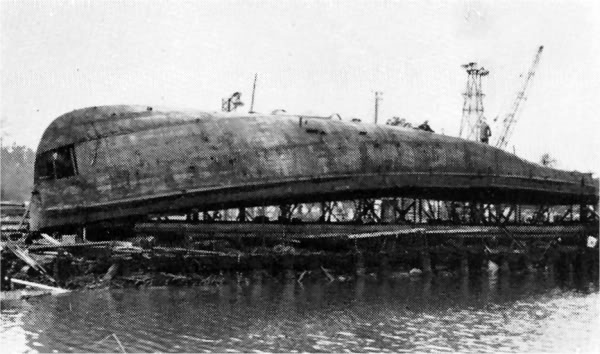

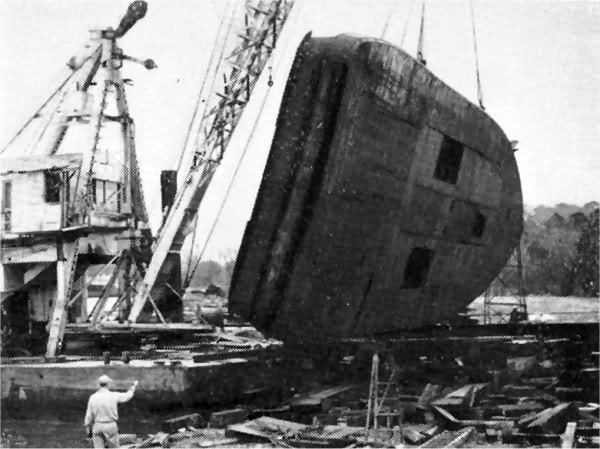

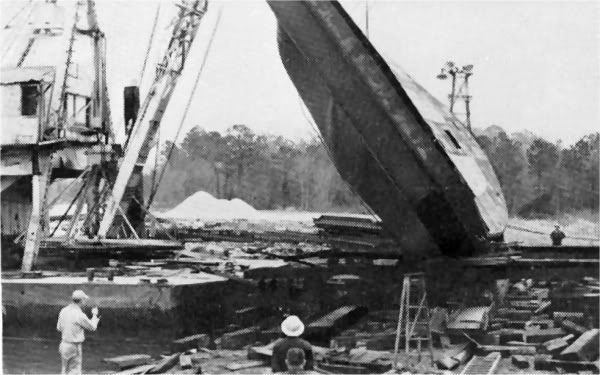

Following a common practice among southern U. S. shipyards, the hull of the ESSO PELHAM

was constructed upside down. Here it is being turned to allow further work to progress.