Auke Visser's International Esso Tankers site | home

Most Modem Bulk Oil Tanker

New Type Condenser, Successfully Used in Stationary Plants, being Installed on 18,000-ton Tanker for

Standard Shipping Company.

THE tanker G. Harrison Smith, latest addition to the fleet of the Standard Shipping Company, is one of the most mo-dern bulk oil carriers afloat.

She is now nearing completion at the yard of the Federal Shipbuilding & Dry Dock Company, Kearny, New Jersey. She is built on the Isherwood Bracketless system of longitudinal framing, while the application of high steam pres-sures and temperatures to her machinery is in accordance with the most progressive developments in marine pro-pulsion.

Her dimensions are 543 feet over-all length, 74 feet beam, and 40 feet 6 inches depth; 'tween deck height main to shelter deck 14 feet 8 inches. Her deadweight capacity is 18,000 tons on a draft of 28 feet 6 inches, and speed on trial 11 knots. Capacity of main cargo oil tanks is about 706,000 cubic feet; capacity of summer tanks about 159,000 cubic feet.

The hull is divided by 17 oil-tight and water-tight transverse bulkheads. There are 11 bulk oil tanks, pump room, fuel oil tank, forward hold, and machinery space. The forward hold is arranged for carrying ballast; and the 'tween decks forward is arranged for carrying stores or miscellaneous freight.

A center-line bulkhead is fitted in the oil tanks extending from the keel to the shelter deck; and expansion trunk bulk-heads, one port and one starboard, extend from main to shelter deck. Wing spaces outside the expansion trunk bulkheads are divided into five compartments on each side, fitted up as summer tanks. The fuel oil tanks have a capacity of about 1300 tons.

Forward there is a raised forecastle containing carpenter shop, lamp room, paint room, and store room. A bridge house is constructed amidship with steel bulkheads at each end. Quarters for deck officers will be provided in a steel house on the bridge deck. Above this house will be accommodations for the captain and radio operator. The wheel house will be equipped with the Sperry gyro-compass and gyro-pilot. Quarters for engineers, petty officers, and the remainder of the crew, the galley, and mess rooms are located in a steel deck house in 'tween decks aft.

Propelling Machinery

The propelling machinery, which is located aft, consists of a De Laval compound steam turbine with double reduc-tion gear, driving a single screw. The normal rated capacity of the turbine is 4000 shaft horsepower; the propeller speed is 75 revolutions per minute, which gives a trial speed of 11 knots. The unit will develop a maximum of 4400 shaft horsepower at 77 1/2 revolutions per minute.

The main turbine is of the cross compound type, with a high pressure turbine and one low pressure turbine in series, connected through flexible couplings to the high speed pinions of the double reduction gears.

The slow speed gear shaft is directly coupled to the propeller shaft. The astern turbine is in the exhaust end of the low pressure ahead turbine. The low pressure turbine and the astern turbine exhaust through the bottom of the ca-sing into the condenser, arranged athwart ship underneath.

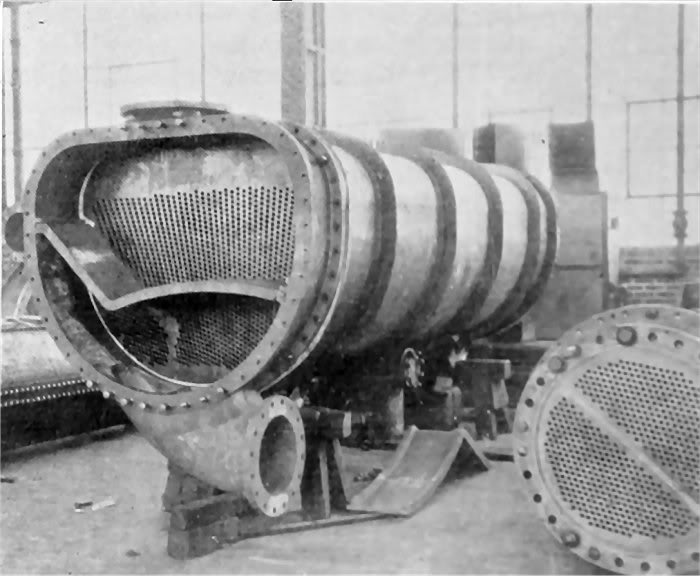

New type of Foster Wheeler condenser installed in the new tanker G. Harrison Smith.

This condenser (designed and built by the Foster Wheeler Corporation) is an interesting feature, being the first of its type afloat, although its merits have been well proved ashore over a period of four years in high pressure steam plants. The special feature is the provision for expansion of the tubes which permits rolling the tube into the tube sheet at both ends while still retaining the most economical arrangement of the nest of tubes.

The tubes are arranged on radiating lines to permit free flow of steam and most effective heat transfer on all tube surfaces. A separate part of the condenser is used for cooling air and noncondensable gases; and provision is ma-de for their thorough removal. Vacuum is maintained by a special steam jet air pump. The main condenser has 4000 square feet of effective cooling surface. There are two auxiliary condensers, each with 600 square feet of effective cooling surface.

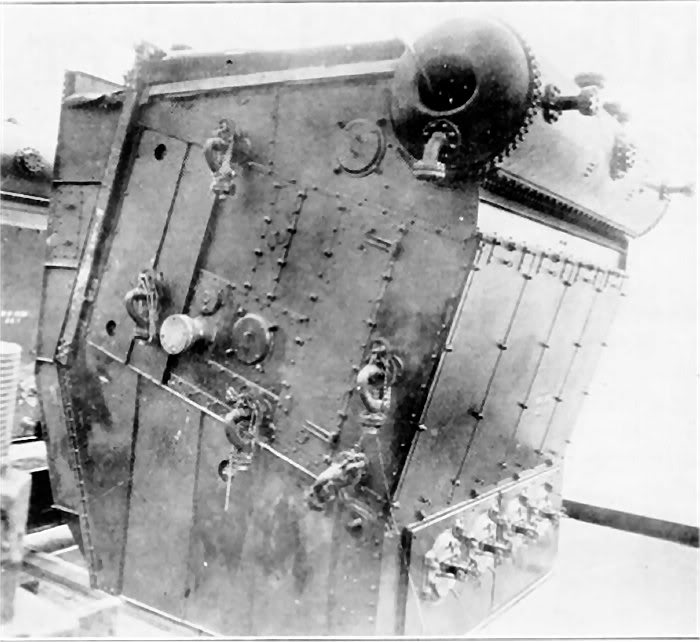

One of the two Babcock & Wilcox marine, water-tube boilers installed on the G. Harrison Smith.

Steam will be supplied to the turbines at 400 pounds per square inch pressure and at a total temperature of 750 de-grees Fahrenheit by two Babcock & Wilcox marine water-tube boilers, each having 5080 square feet of boiler heat-ing surface, 903 square feet of superheating surface and 3460 square feet of air heating surface.

Boiler safety valves will be set for 425 pounds per square inch.

The superheaters are of the interdeck type, amply shielded from the radiant heat of the furnace, and are located en-tirely within the boiler casing.

The two boilers are arranged side by side with an athwartship firing aisle. The air heaters are located on top of each boiler. They are of the horizontal tyne and are designed to give added efficiency to the units by reducing the exit gas temperatures from the boilers and supplying preheated air for combustion. Air for combustion passes through the tubes, while the gases pass over them. Babcock & Wilcox float-type feedwater regulators are fitted to each boiler drum to control the amount of feed and the level of the water in the boilers.

Each boiler is fitted with a Babcock & Wilcox internal desuperheater to furnish steam for auxiliary purposes. These desuperheaters, being entirely within the boilers, operate without heat loss. Their action is entirely automatic and the apparatus is of extremely simple and rugged design. All steam passes through the superheaters, and the required amount is then desuperheated.

The desuperheaters provide saturated steam for auxiliaries while the ship is in port, such a procedure preventing ex-cessive superheat temperatures and affording additional protection to the superheater tubes when the main engines are not in use and a minimum amount of superheated steam is required.

The boiler furnaces are lined with Babcock & Wilcox No. 80 firebrick and special insulation to permit the use of pre-heated air for combustion and operation at continued high ratings with a minimum amount of refractory mainte-nance. This material is being installed in the boilers of practically all of the recent American merchant vessels.

A single installation of six Diamond Power Specialty Corporation automatic Valv-in-Head, type GOB, soot blowers, consisting of two 2-inch Dialoy, one 2- inch calorized unit, and three 2-inch plain units, is found on each boiler. This installation serves the boiler and superheater jointly. In addition, each air heater will be cleaned by a double instal-lation consisting of six 2-inch units of the same design.

Source : Pacific Marine Review, Volume 27, October, 1930.

|