Auke Visser's International Esso Tankers site | home

First American Arcform Tankers - Part-1

Source : Marine Pacific Review, Volume 33, January, 1936.

Building Two Steam Turbine Drive Single Screw Tankers of the Isherwood Arcform Design at the Federal Shipbuilding and Dry Dock Company.

Early in 1934, the Federal Shipbuilding and Drydock Company sensed the great need for new American tanker tonnage. The technical staff of the yard was ordered to make a study of hull forms and of the particular needs of oil companies as to size and speed. Several models were tested in the towing tank, and considerable experimenting was done with hull appendages.

As a result of this preliminary work, a design was prepared for an Isherwood Arcform single-screw hull that would carry 12,500 tons deadweight on 28-foot draft; would have a capacity of 100,000 barrels of oil cargo; and would maintain a sea service speed fully loaded of 11.75 knots on 3000 shaft horsepower.

In January, 1935, the keel for a ship to be built to this design was laid down at the yard on the yard’s account and a month or two later the keel was laid for the second tanker.

That this speculative building was fully justified is amply proven by the fact that the Standard Shipping Company, largest tank operators in the world, bought these two tankers while they were still in frame on the stocks.

Shortly after this purchase, the two hulls were named after two officials of the Standard Oil Company.

The first, Hull No. 136, received the name of R. P. Resor, treasurer of the Standard Oil Company of New Jersey, and the second, Hull No. 137, took the name of T. C. McCobb, mem- ber of the Board of Directors and Comptroller of the same company.

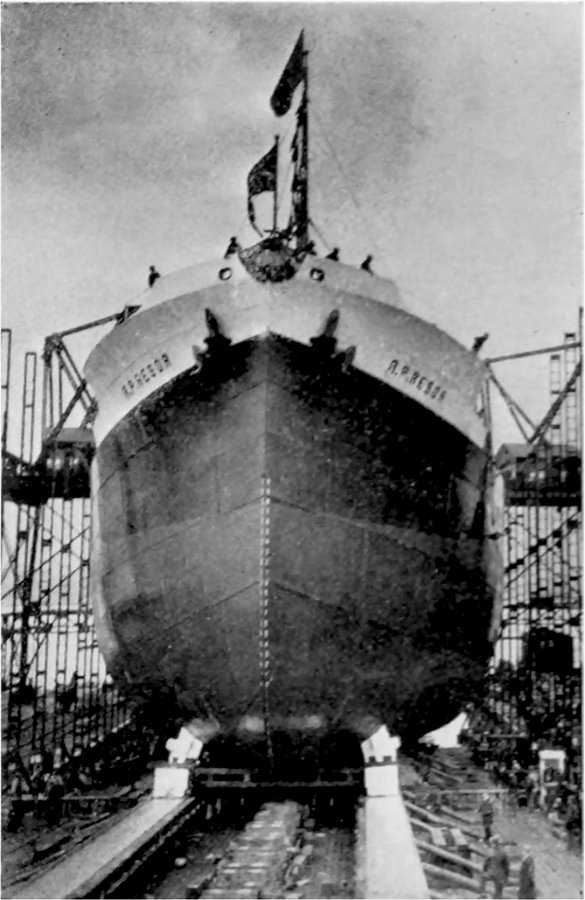

Bow view of tanker R. P. Resor sliding down the ways.

While the design of the tankers is conservative as to size, speed, and steam conditions, there are a number of features included in the hull which make them the first of their type to be built in American shipyards, and a number of items in their machinery equipment which are first installations anywhere. These facts taken in conjunction with the present great need of new American

tanker tonnage led the Pacific Marine Review in cooperation with the builders and owners of these vessels to prepare a fully illustrated detail description of the design, construction and equipment thereof.

The design calls for construction on the Isherwood longitudinal, bracketless system to the patented Isherwood Arcform lines. Isherwood Arcform is comparatively recent in development. It was brought out by Sir Joseph Isherwood, noted British naval architect, in 1932, and first used in the design of the steamer Arcwear, a steam freighter of 7080 tons deadweight capacity, built by

Isherwood for his own account. This vessel, on her trials in January, 1931, exceeded all expectations as to propulsive economy. S.S. Arcwear and several other European Arcform ships have maintained exceptionally good performance records in sea service. Exhaustive model tests at the British towing tank at Teddington and at the U.S. towing tank at Washington indicate savings in power for a given speed of from 13 to 15 per cent over normal tanker forms and on this basis it was predicted that the tankers building at Federal Shipbuilding and Drydock Company would attain a speed of 13 knots on trial and could maintain 12 knots at

sea fully loaded. Due to the increased capacity given by this form, these tankers will carry their full capacity — 100.000 barrels in gasoline.

This capacity is said to be the largest yet attained in any tanker of the same overall dimensions.

A very decided advantage of the Arcform is that it maintains the propulsive efficiency of a ship within very narrow limits over a wide range of speeds. Considered, therefore solely from the point of view that they are America's first Arcform hulls, performance of the tankers. R. P. Resor and T. C. McCobb will be watched with great interest by American tanker operators.

In the detail design and construction of the hulls there are several features worthy of note. First, all bottom plating is lapped with the

outside butt facing forward instead. of aft, and these butts are nicely half rounded. This is expected to give an appreciable addition to propulsive efficiency.

Second, welding is used wherever safe and practicable. A full riveted hull of the same type and size would take over a million rivets. Only 340,000 rivets were used in each of these hulls. The longitudinal bulkheads in cargo tanks and much of the transverse bulk heading are fully welded.

Much of the superstructure is welded and many hull appendages. All piping over 11/1; inches diameter is welded throughout.

Third, the stern of each ship is fitted with contra-propeller sternpost, and in addition the Federal contra-guide rudder is used.

Fourth, they are the first ships to be finished and equipped to the new rules of the United States Steamboat Inspection Service which include some new ideas in fire-proof construction and a number of new items in safe navigation and life-saving equipment.

Fifth, in the propulsion machinery, we find a new design of. and location for, the steam generating plant, and some details of turbine construction new in marine application.

General Description

The ships are single screw bulk oil tankers, driven by cross compound impulse reaction steam turbines connected to the propeller

shaft by double reduction helical gearing. Steam for the turbines is supplied by watertube boilers. The hull carries two masts and a streamlined stack, and has the usual tanker bridge and pilot house erection connected by an elevated walkway to the poopdeck and afterhouse.

Each hull is divided into 14 watertight compartments by 13 bulkheads. From stem to stern these compartments include: forepeak tank with stores above; ballast tank with dry cargo above; forward cofferdam; cargo oil tanks Nos. 1, 2, 3, 4, 5, 6, and 7; after cofferdam; fuel oil tanks; machinery space; and afterpeak tank. Each cargo tank is divided by two longitudinal bulkheads into three compartments. As indicated on the general arrangement and machinery arrangement plans herewith, the cargo pumproom is located just forward of the machinery space and between the two wing fuel oil tanks.

The principal general characteristics of these hulls are :

The bows have considerable flare, an important ftature in the Isherwood Arcform design, and one which has proved of great advantage in steaming into head seas.

Machinery Spaces

The arrangement of all machinery and the principal equipment is shown very clearly on the plans in the insert and on pages 17, 18, and 19 - also a full list of items with index numbers for reference on the plans.

Specifications for machinery include the following stipulations of interest to engineers:

The propulsive machinery to be built to meet requirements of American Bureau of Shipping and U.S. Steamboat Inspection Service. and to be classed by the American Bureau.

Quartering view of R. P. Resor in the stream after launching.

Engine room ladders to be of inclined type where possible, to have steel side bars and cast iron treads, and to be furnished with dust pans of galvanized steel. All engine room gratings to be Carnegie staggered tread type, except the operating platform which will be of Kerlow type grating. All engine room hand rails

to be 1 inch diameter, cold rolled steel.

Extra photos on Part-2 and text to be continued on Part-3

|

See also : First American Arcform Tankers - Part-2