Auke Visser's International Esso Tankers site | home

First American Arcform Tankers - Part-7

Source : Marine Pacific Review, Volume 33, January, 1936.

Fireproof Bullsheads and Ceilings

In arriving at materials to anticipate proposed regulations relating to fireproof construction, it was recognized that features beyond mere fire resistance merited attention.

Insulation. both thermal and sound, resistance to normal abuse and capacity for decoration were all obviously desirable, immunity to continued high humidity and satiafactory atiffneas, as well an mechanical strength to meet the vibration and working of a ship, were definite requirements.

For cabin bulkheads and passageway enclosure, the builders selected a panel composed of a 1-inch thick vitrified and waterproofed asbestos core,as manufactured by Johns-Manville which was faced with No. 26 gauge galvaneal steel and furnished

as completed panels, cut to size, by the Haskelite Manufacturing Corporation. The weight is about four pounds per square foot.

Ceiling panels with the same core but veneered with 1/16-inch asbestos flexboard, in lieu of the steel and weighing about 3.0 pounds per square foot, were made and furnished by Johns-Manville.

Where changes in plans necessitated it, panels were cut to exact size on the job. All edges were sealed, the panels covered with decorative steel battens.

Panels, with both steel and asbestos flexboard finishes were tested under the N.F.P.A. Recommended Regulations for Marine Construction exceeded the one hour test for integrity of structure, as well as meeting requirements of temperature rise, under the standard A.S.T.M. 1700 degree cure. Strength tests were made, as well as tests to determine the necessary immunity to prolonged high humidity and to the effect of rapid changes in temperature in coming from southern to northern waters.

Sound transmission indicated a considerable greater resistance, or sound isolation, than with an equal thickness of plywood. To show the thoroughness with which Hopeman Brothers studied the problem, tests were made to simulate a steam leak in proximitly to a panel, so as to establish the adhesion of the facing material to the core under such acondition.

From the standpoint of comfort, aside from being fireproof, the quarters are superior to those of passenger vessels embodying wood or other organic panels with equally attractive appearance for the same veneer or finish selected.

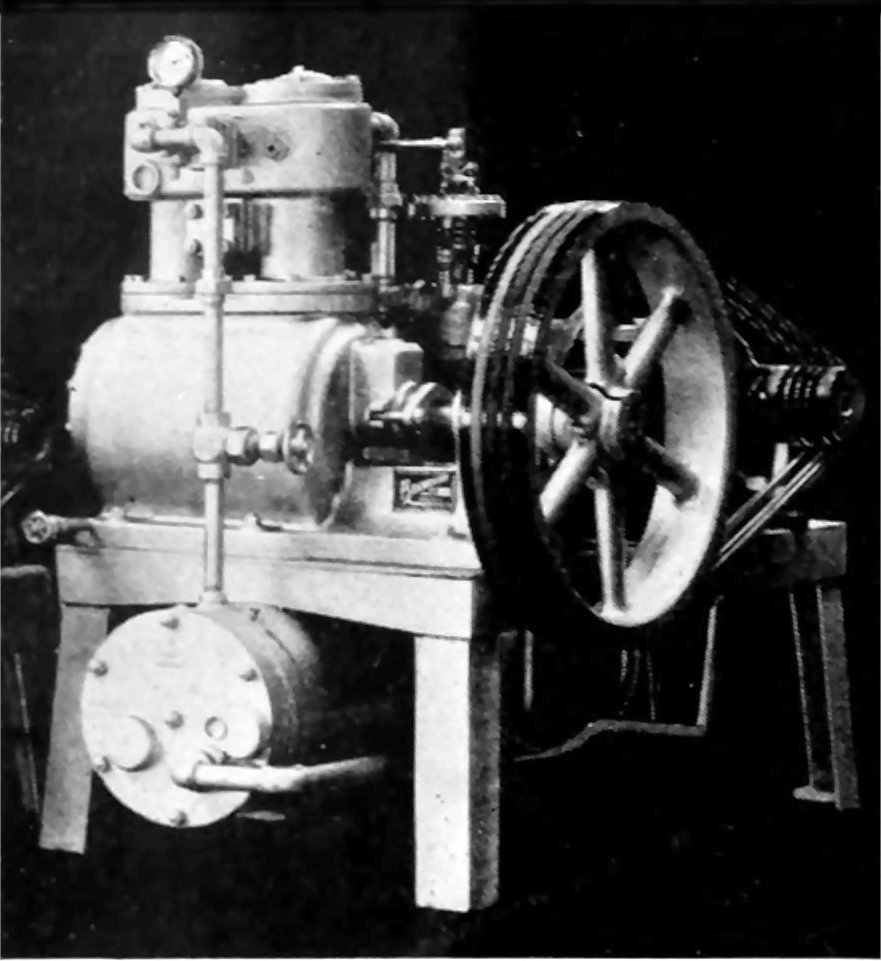

Above: Carrier self-contained ammonia refrigerating unit as installed on R. P. Resor.

Refrigerating Equipment

The ship's stores refrigerators consist of a two-compartment box, divided approximately in half. One compartment is designed for the storage of frozen meat at a temperature of 20 degrees to 24 degrees and the second compartment is arranged for storing perishable products, such as vegetables, fruit, etc., at a temperature of approximately 40 degrees.

In addition, a water cooler is pro- vided to supply chilled drinking water throughout the vessel at all times.

The refrigeration is effected by means of a Carrier Self-Contained Ammonia Refrigerating Unit. This unit is of a very compact design. The base is especially arranged so that the compressor and motor are mounted on top and a condenser, of the shell and tube type, is mounted underneath. Four substantial legs permit securing the entire unit to the deck without the necessity of constructing special foundations. A minimum. of deck space is required and the necessity of furnishing special brackets, hangers and foundations, usually considered as part of refrigerating installations, is entirely eliminated.

Cooling in the refrigerated compartments is effected by means of extra heavy galvanized steel coils properly valved to permit individual temperature adjustment.

A constant supply of cooled water is available in various parts of the ship for the comfort of the crew, the water being supplied from a water cooler also connected to the refrigerating plant. This added comfort and convenience has proved to be very beneficial and a decided factor in increasing the efficiency of the crew, particularly while the vessel is in warm or tropical climates. The entire system is of substantial design with moderate operating speed, in accordance with the usual rigid requirements as set forth by the Standard Shipping Company.

|