Auke Visser's International Esso Tankers site | home

NEW DIESEL-ELECTRIC TANKER - Part 1

Source : Pacific Marine Review, Volume 21, May, 1924.

Standard Oil Company of New Jersey Adds to Its Fleet a Westinghouse-Equipped Selt-Propelled Tank Barge.

First of Its Type on Atlantic Coast.

J. H. Senior.

In February, 1924, there occurred at Chesapeake Bay a rather remarkable incident in the history of the American merchant marine. On that occasion J. H. Senior, chairman of the Marketing Committee of the Standard Oil Company of New Jersey, stepped into the pilot house of a new barge tanker, named after himself, and took over the control of this tanker into his own hands with no more preliminary instruction than would have been necessary had he been exchanging his old car for a new model. Without notice to the engine room, he spun a small wheel around until the arrow, which had been pointing full speed forward, indicated full speed astern.

As he did so, R. L. Haig, manager of the Marine Department, snapped his stop watch. In exactly one minute and thirty seconds the boat had lost headway and was beginning to move backwards. Putting her at full speed ahead once more, Mr. Senior then maneuvered the electric telemotor and steered at will around the harbor, the vessel maneuvering as easily as an automobile.

The J. H. Senior was built by the Newport News Shipbuilding & Drydock Company to plans and specifications drawn up by the Standard Oil Company of New Jersey. She was intended for use in delivering bulk cargoes of gasoline and refined oils to points

served by the Baltimore division, notably Washington and Richmond. She is 208 feet long with 38 feet beam

and has a carrying capacity of 11,500 barrels on a draft of 13 feet.

The propelling machinery consists of two 6-cylinder 350 horsepower non-reversible Mcintosh & Seymour diesel engines, each direct-connected to a 185 kilowatt 115 volt Westinghouse direct current generator. These two generators supply current to a 450 horsepower single armature Westinghouse motor direct-connected to the propeller shaft, which is turned at 100 revolutions a minute.

The placement of the machinery in the engine room will be noted from the arrangement plan herewith, the two main engines and generators being set on a diagonal line with the driving motor set between them near their forward end, and so making an ensemble that permits of the machinery being placed further aft than would otherwise be possible. The machinery is designed to drive the hull loaded at a speed of 8.5 knots an hour. The propeller is of the solid 4-blade type, 10 feet in diameter and 10 feet pitch, with a developed area of 32.4 square feet.

Mcintosh & Seymour Engines

The Mcintosh & Seymour engines used in the J. H. Senior are of the standard, heavy duty, slow speed type, developing 350 brake

horsepower at 275 revolutions per minute. There are 6 cylinders on each engine of 13- inch bore and 17-inch stroke, working on a 4 cycle principle. For each main engine there is installed a 1 1/2 cubic foot injection air bottle and a 10 cubic foot starting air bottle. These bottles are both charged with air at 1100 pounds per square inch pressure.

The main cargo oil pumps and all of the auxiliaries of the ship, both in the engine room and on deck, are electrically operated, the current being used for this purpose from the main generators or from the auxiliary set, which consists of a Fairbanks Morse type

"CO" engine, 3 cylinder, 2 cycle, 45 horsepower at 400 revolutions per minute, direct-connected to a 30 kilowatt 125 volt Fairbanks Morse generator. This auxiliary generating set is provided with an emergency hand power air starting system. A small electric

motor-driven air compressor for initially charging the air bottles is run on this auxiliary generating set.

Auxiliary Machinery

The cargo oil pumps were supplied by the Northern Pump Company to the designs of the Marine Department of the Standard Oil Company of New Jersey. They are of the rotary type, figured to deliver 375 gallons per minute against 100 pounds pressure at 300 to 426 revolutions per minute with an 8-inch diameter suction and a 6-inch discharge. The pumps are located in a watertight pump room extending clear across the hull, just forward of the engine room and insulating the engine room from the cargo tanks. The pumps are driven through gearing by 35 horsepower 115 volt 800 to 1150 revolutions per minute Westinghouse compound wound motors, the motors being located in the forward end of the engine room, and the pump shafts carried through oil-tight stuffing boxes in the engine room bulkheads.

The circulating water pumps are De Laval centrifugals, 3-inch suction by 3-inch discharge, directconnected to Westinghouse 5 horsepower compound wound motors running at 1700 revolutions a minute.

The sanitary, bilge, and fuel oil transfer pumps are supplied by the Northern Pump Company and driven by Westinghouse motors. A one-half ton Brunswick refrigerator outfit is installed.

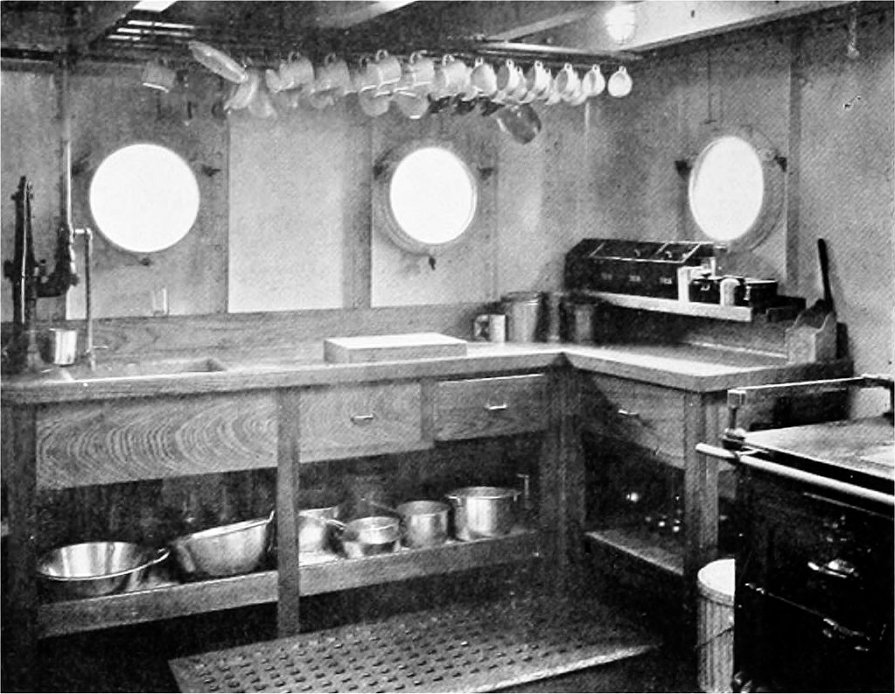

The electric galley of the new diesel-electric tanker J.H. Senior.

Electrical steering gear was supplied by the Allen Cunningham Company of Seattle. The motor gearing and drum are housed in an extension of the deckhouse aft on the main deck, the drum being connected by a chain to the quadrant on the rudder stock. The

position indicator consists of a series of colored electric bulbs fitted in the control stand which show every 2 1/2 degrees for initial angles and every 5 degrees for wider angles of helm. It is of the non-follow-up type, the motor running continuously until the helm is hard over, so long as the control lever is on center.

Stern Tube Bearings

An interesting feature of the propulsion machinery is the stern tube bearings. Two "Cutlass" rubber bearings, supplied by the Goodrich Rubber Company, are fitted one at the forward and one at the after end of the tail shaft liner. These bearings permit of practically perfect lubrication and exclude all sand and grit, thereby tending to greatly increase the lives of the liners as well as of the bearings themselves.

Crew's Quarters

Quarters for engineers and deck crew are fitted in the deckhouse aft, surrounding the engine hatch. These quarters give very comfortable accommodations for eight men, including chief engineer, assistant engineer, three seamen, one oiler, a cook, and a boy.

A commodious ice box alongside the ice machine is fitted to take care of galley stores, and the galley and messroom are conveniently laid out athwart ship at the after end of this superstructure. Quarter.s for the captain and the mate are fitted on the bridge deck forward.

Pilot House Control

In the main propelling machinery of the J. H. Senior the two main generators are operated in series and are direct-connected electrical through suitable switchboard control to the propelling motor.

The main engines and generators maintain a constant speed for all loads. At the after end of each generating set there is directly connected a 35 kilowatt 11.5 volt exciter for the field current of the generator and the motor. All variations in the propeller speed are controlled through the varying of the strength of the current in the field windings of the main generators on the Ward-Leonard system, in the same way that the majority of the street car motors of America are controlled by the motorman. Thus the

maneuvering of this 220 foot 2300 ton craft is effected by a small lever in the pilot house as easily as the average American citizen manages his motorcar.

This installation is, we believe, the first of its kind to be installed in a tanker on the Atlantic Coast.

|