FSO / FPSO > 200.000 DWT | home

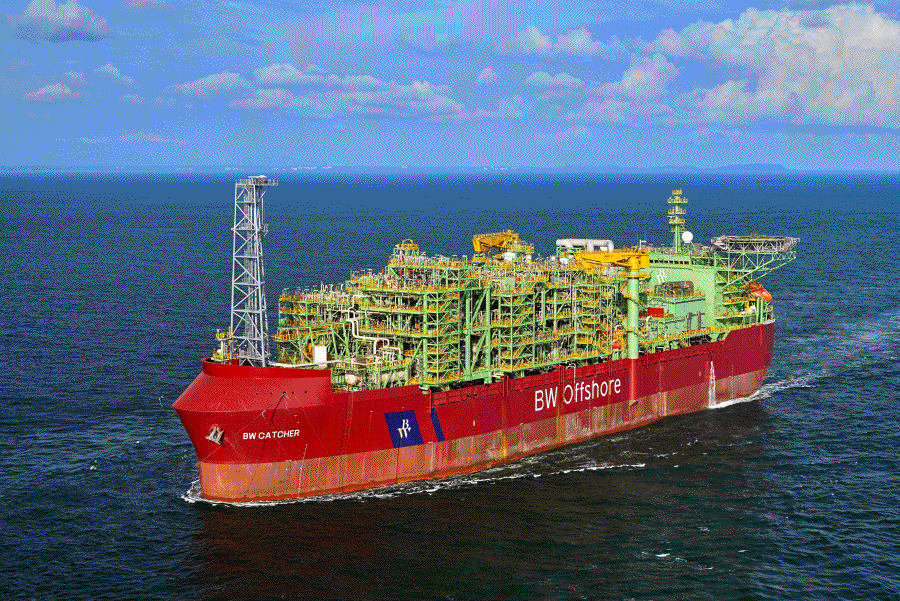

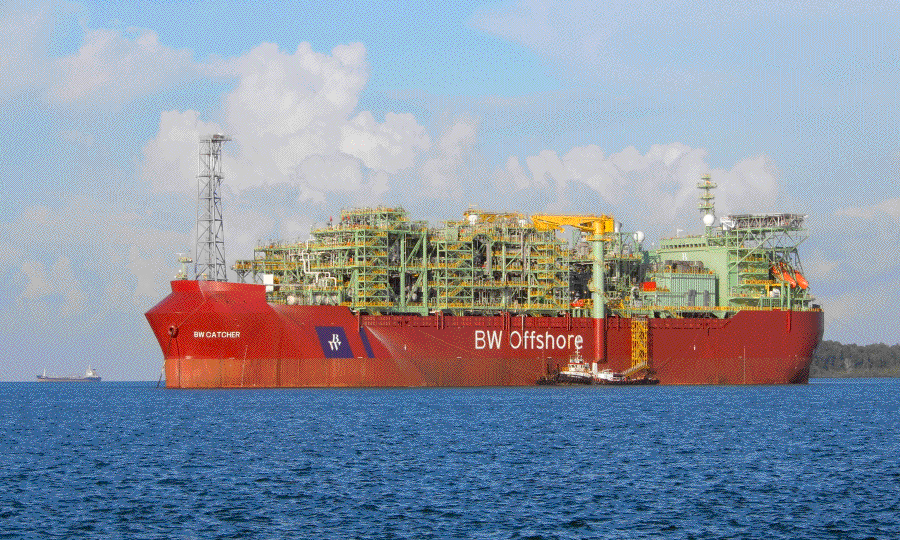

BW Catcher

See also : 3 Video's "BW Catcher"

"BW Catcher".

( Photo Copyright BW Offshore )

"BW Catcher", at anchorage for final commissioning before transit to the UK, August 20th, 2017.

( Photo Copyright Steve Baron )

"BW Catcher" outfitting at Keppel, Singapore.

( Photo Copyright BW Offshore )

( Photo Copyright BW Offshore )

BW Catcher :

Main Contractors

|

Processing Capacity

|

||

Topsides Module Engineering:

|

Aibel Singapore

|

Topsides Weight (Dry / Operating)

|

13,400 Mt / 16,600 Mt

|

New-Build Hull Engineering:

|

IHI Japan

|

Total Liquids Capacity:

|

125,000 bpd

|

Turret/Swivel Supplier:

|

APL Norway

|

Oil Processing Capacity:

|

60,000 bpd

|

Topsides Module Fabrication:

|

Dyna-Mac, Singapore

|

Gas Handling Capacity:

|

60 MMscfd

|

Fabrication Yard:

|

Kongsberg, Singapore

|

Produced Water Capacity:

|

125,000 bpd

|

Fjords Norway

|

Water Injection Capacity:

|

125,000 bpd

|

|

Integration Yard:

|

Keppel, Singapore

|

Available Deck Area for Expansion:

|

19.9m x 11.9m

|

Well Information

|

Mooring & Offloading Information

|

||

Total Wells:

|

22 (incl. 4 Future)

|

Mooring Type:

|

Internal Turret

|

Production Wells:

|

14

|

Permanent or Disconnectable:

|

Permanent

|

Water Injection Wells:

|

8

|

Mooring Line Pattern:

|

3 Clusters of 4 Lines

|

Tree Installation Type:

|

Wet Tree

|

Anchor Type:

|

Driven Pile Anchor

|

Artifical Lift:

|

Gas Lift

|

Mooring Line Configuration:

|

Chain + Wire

|

Offloading System:

|

Stern Discharge System, SDS

|

||

Hull Information

|

|||

Length overall:

|

240.9 m

|

Riser Information

|

|

Breadth:

|

50 m

|

Total Risers and Umbilicals:

|

17

|

Depth:

|

27 m

|

Production Risers:

|

3 x 6" (+ 1 Future)

|

Storage Capacity:

|

106,523 m3 (Cargo)

|

Water Injection Risers:

|

3 x 8" (+1 Future)

|

Tank Heating:

|

Yes

|

Gas Injection Risers:

|

0

|

Max Operating Draft:

|

18.5 m

|

Gas Lift Risers:

|

3 x 6"

|

Hull Construction Type:

|

Double-Sided &

|

Gas Export / Import Risers:

|

1 x 10"

|

Bottom Hull

|

Umbilicals:

|

3 (+2 Future)

|

|

Accommodation:

|

120 Persons

|

Other:

|

0

|

Conversion or New Build:

|

New Build

|

||

Accommodation Fabricator:

|

AMTEC, Japan

|

Essential Power Generation

|

|

Total Installed Power:

|

12.68 MW

|

||

Main Power Generation:

|

Generator Configuration:

|

2 x 100%

|

|

Generator Type:

|

GTG, Solar Titan 130

|

Voltage:

|

11 kV

|

Total Installed Power:

|

43.2 MW

|

||

Power per Generator:

|

14.4 MW

|

Emergency Power Generation

|

|

Generator Configuration:

|

3 x 50%

|

Total Installed Power:

|

1.65 MW

|

Voltage:

|

11 kV

|

Generator Configuration:

|

1 x 100%

|

Voltage:

|

690V

|

||

Oil Processing

|

|||

Design Total Liquids:

|

125,000 bpd

|

||

Design Oil Flowrate:

|

60,000 bpd

|

||

Inlet Sep. Design Pressure:

|

FV / 15 barg

|

||

Inlet Sep. Design Temperature:

|

-15 / 100 C

|

||

Materials of Construction:

|

Vessels (Duplex SS, SS316, CS with Corrosion Allowance), Piping (Duplex SS, CS with Corrosion Allowance)

|

||

Design Oil API:

|

24.9 (Burgman); 26.8 (Varadero); 29.7 to 30.4 (Catcher)

|

||

Configuration:

|

2 Stage Separation with Pre-heat upstream of 1st Stage and Test Separators, and Interstage Heating Upstream

|

||

of 2nd Stage Separator. Electrostatic Coalescer. Fiscal Meetering of Offloaded Crude.

|

|||

Test Separator Capacity:

|

30,000 bpd of Oil

|

||

Gas Handling

|

|||

Design Flowrate:

|

60 MMSCFD Export Gas (Key Specifications: CO2 1.6% mol. H2S 2.5 ppmv, H2O 35 ppmv

|

||

Compression Capacity:

|

Flas Gas Comp 3.0 MMSCFD; Booster Camp 79.6 MMSCFD; Export Gas Comp 66.4 MMSCFD;

|

||

Permeate Gas Comp 6.43 MMSCFD

|

|||

Configuration:

|

Flash Gas Comp from 2nd tage Separator, Booster Comp from 1st Stage Separator plus FGC Discharge,

|

||

Gas Dehydration, CO2 and H2S Removal, Gas Dewpointing, Export Gas Comp, Export /Import Fiscal Metering,

|

|||

Permeate Gas Comp, Cargo Tank Blanketing with LP Fuel Gas and with Vapour Recovery Unit

|

|||

Compression Power:

|

Flash Gas Comp 533 kW; Booster Comp 9,400 kW; Export Gas Comp 4,730 kW; Permeate Gas Comp 1st

|

||

Stage 773 kW; Permeate Gas Comp 2nd Stage 773 kW (All Electric Driven)

|

|||

Gas Treatment:

|

Gas Dehydration, TEG Regeneration, CO2 Removal, H2S Removal

|

||

Gas Export Pressure:

|

150 barg in Export Gas Pipeline

|

||

Gas Lift Pressure:

|

74 barg (Turndown) to 130 barg (Maximum Flow) at top of Lift Gas Risers

|

||

Materials of Construction:

|

Vessels (Duplex SS, SS316, CS), Piping (Duplex SS, SS316, CS with Corrosion Allowance)

|

||

Produced Water

|

|||

Design Flowrate:

|

125,000 bpd Treated Produced Water

|

||

Treatment System:

|

De-oiling Hydrocyclone, and Compact Floatation Unit (CFU)

|

||

Disposal Route:

|

Re-Injection (Can be diverted to Off-Spec Tank or Overboard)

|

||

Materials of Construction:

|

Piping (Duplex SS); Vessels (Duplex SS and Epoxy Lined CS)

|

||

Water Injection

|

|||

Total Water Injection Capacity:

|

125,000 bpd

|

||

Seawater Flowrate:

|

75,000 bpd Treated Seawater

|

||

Produced Water Flowrate:

|

125,000 bpd (Without Seawater Injection)

|

||

Seawater Treatment:

|

Filtration 98% >5?; Max Dissolved Oxygen <10ppb (Vacuum Desorption); Max Sulphate Content 200 mg/l

|

||

Pump Discharge Design Pressure:

|

190 barg

|

||

Pump Normal Operating Pressure:

|

150 barg at 62,500 bpd Flow per Pump

|

||

Pump Configuration:

|

3 x 50%

|

||

Materials of Construction:

|

Vessels (Glass Flake Lined CS, GRE); Pumps (SS316, Duplex SS)

|

||

Seawater Systems Piping Materials

|

|||

Firewater System:

|

GRE / CuNi / Super Duplex

|

||

Seawater:

|

GRE / Carbon Steel with PE Coating

|

||

Injection Water:

|

GRE / SS316L / Duplex SS

|

||

Steam Systems

|

|||

Auxiliary Boilers:

|

2

|

Low Pressure Steam Generator:

|

1

|

Capacity per Boiler:

|

20 TPH

|

Heat Duty:

|

11.2 kW

|

Steam Generation Pressure:

|

16 barg

|

Steam Generation Pressure:

|

16 barg

|

Fuel System:

|

Fuel Gas / MGO

|

||

Info : BW Offshore