Auke Visser's Famous T - Tankers Pages | home

On the Ways

LARGEST STRAPPING JOB ON THE COAST

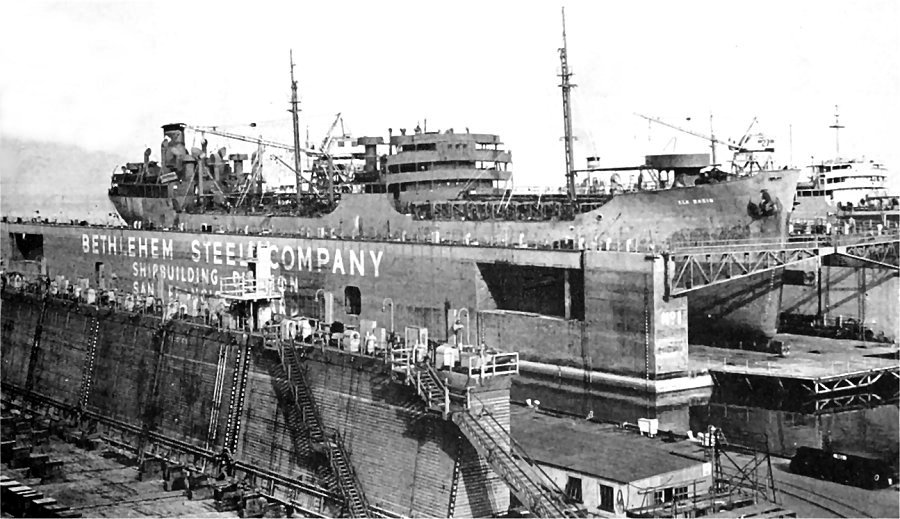

"Elk Basin" in Drydock at the Bethlehem's San Francisco Yard.

The largest "crack arrestor" or "strapping" job on the Pacific Coast has just been completed at Bethlehem's San Francisco Yard. This job, which was accomplished in the record time of 18 working days, was performed on the T-2 tanker Elk Basin, recently purchased from the U.,S. Maritime Commission by General Petroleum Company. It far exceeded requirements set up for this

type of vessel by the U. S. Coast Guard and the American Bureau of Shipping in that 8 straps were installed instead of 4. This was because it was General Petroleum Company's wish to give further than the required protection to the ship and her crew.

The eight straps were installed as follows: one on each side of the keel on the bottom and deck of the ship, and two on each side, one just below the sheer strake and one just above the bilge strake. Cuts in the shell and deck plating, over which these straps were riveted, were made with an oxyacetlyene burning machine specially designed by engineers at the yard. This machine will make precision flame cuts in a vertical or horizontal position which are free from any irregularities.

The two bottom straps were installed just outboard of the longitudinal bulkhead with two rows of rivets on each side of the cut. The

two lower side straps were installed just above the turn of the bilge and just below the sheer strake with three rows of rivets on each side of the cut. The two bottom straps consisted of 7/8" plate; the lower side shell straps 1" plate and the upper side shell straps of 1 1/4” and 1” plate; the two deck straps 1" plate.

In addition to installing eight straps on the Elk Basin, Berhlehem's San Francisco Yard also carried out the latest recommendations of the American Bureau of Shipping as to stiffening on the center line transverse bulkheads. This additional work, which was accomplished in conjunction with the strapping, required considerable planning and coordination. This was so that after bottom straps and the lower side shell straps were installed, a flood test of the wing tanks above the side straps could be conducted to insure tightness of the straps and to elirninate the problem of flooding the centerline tank.

Another important feature of the work on the Elk Basin was the installation of a three-cargo pipe segregation system, enabling the vessel to carry three types of oil cargo at any one time without the danger of one contaminating the other.

On completion of the above wotk, all wing cargo tanks, port and starboard were filled and headed to 8’ above the rnain deck to insure tightness between the tanks and to check the stoppers in way of the newly installed straps. In connection with this work it was also necessary to remove and relocate a total of 16 wheel stands and operating rods and install new ones for operating the new3-cargo pipe segregation system.

In addition to strapping the Elk Basins, installing a 3-cargo pipe segregation system and performing various structural modifications, Bethlehem also performed normai voyage repairs on the vessel, removed the complete mechano flight deck, the

gun foundations fore and aft, the magazine in the fore peak and after peak tanks and restored these tanks to the required additional stiffening of their original design.

All strapping and structural modifications were performed under U.S. Cuast Guard and American Bureau of Shipping inspection.

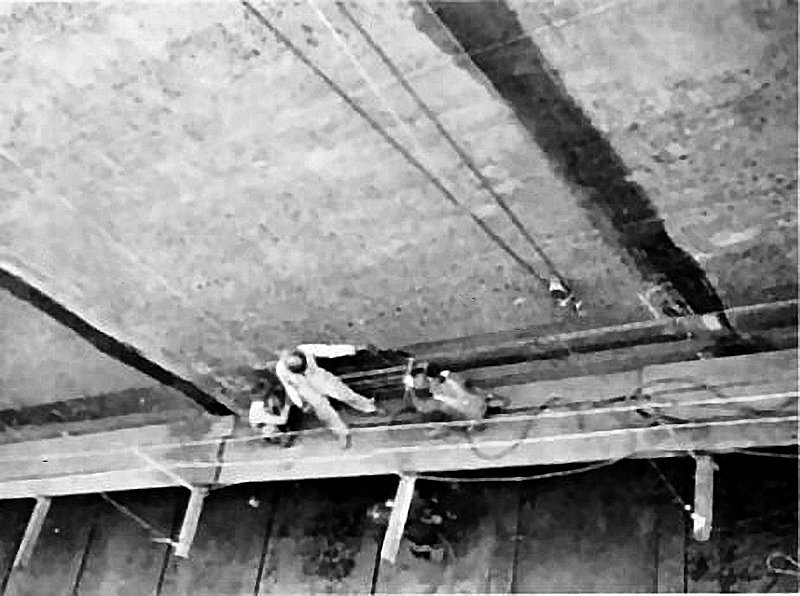

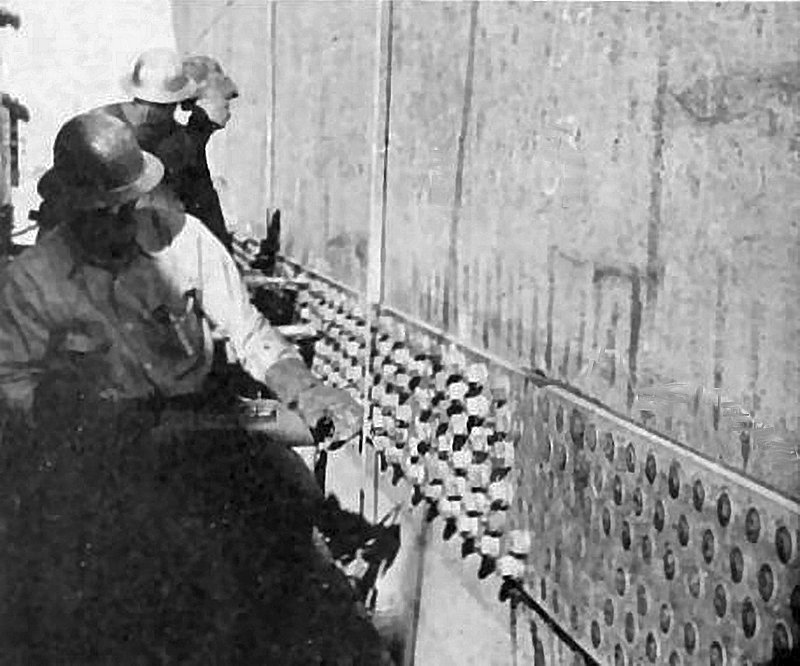

Top :Specially designed burning machine making lower side shell cut.

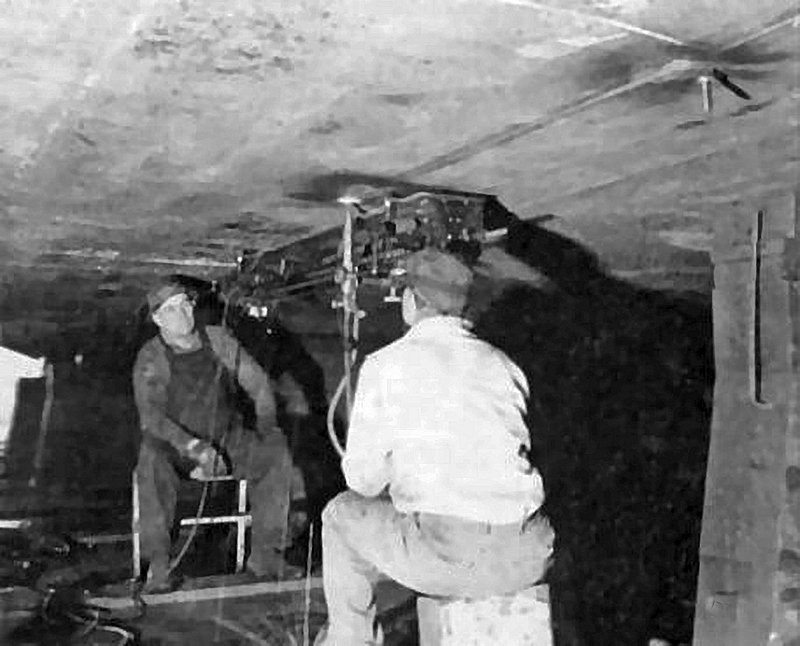

Below: Oxy-acetylene burning machino, designed at Bethlehem Stee Company San Francisco yard, shown making a Bottom cut on the Elk Basin.

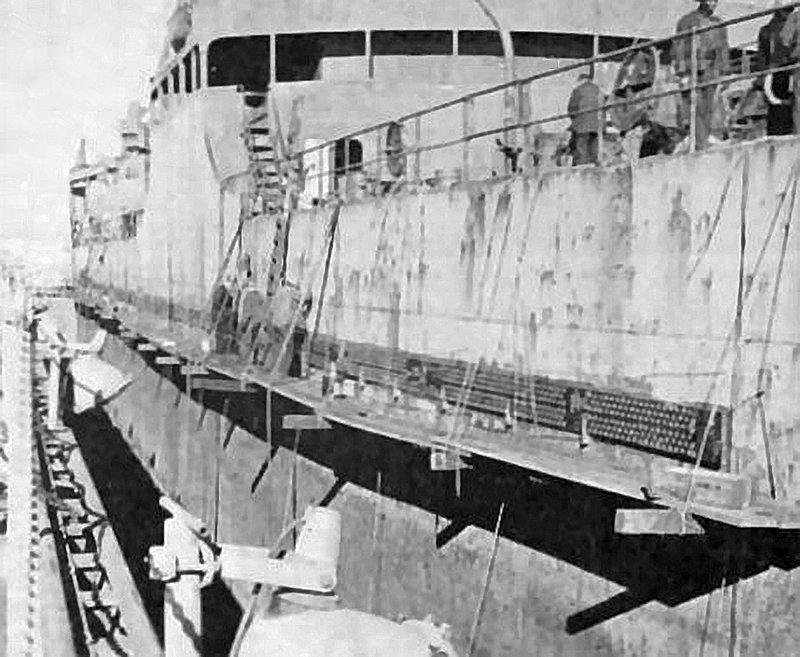

Top: Upper -side shell strap.

Below: Rivet gang driving rivets on Iower side shell strap. 36,000 rivets were requirad for the Elk Basin strapping job, all of these produced in the Bolt and Nut Department of Bethlehem Pacific Coast Steel Corporation’s South San Francisco Plant.

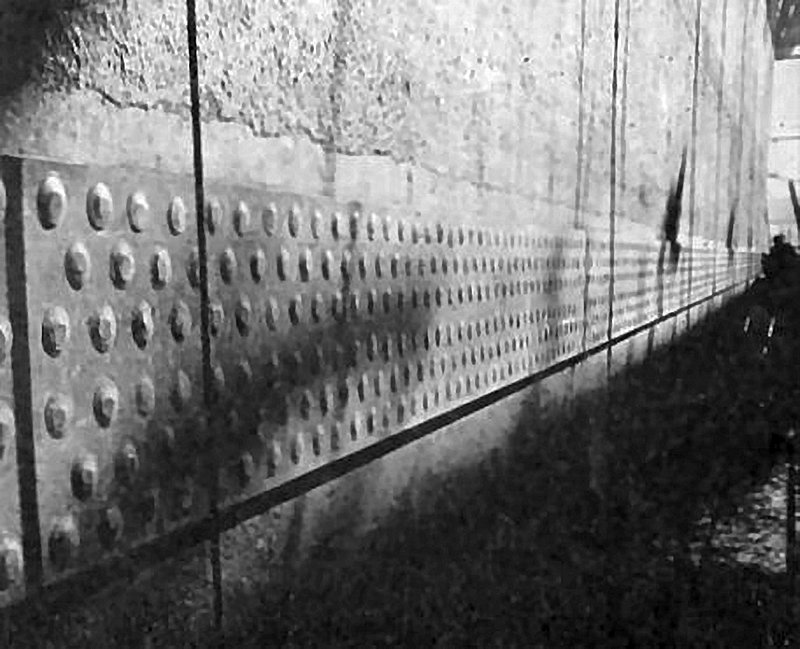

Completed lower side shell strap.

Source : Pacific Marine Review, Volume 45, February 1948.

|