Auke Visser´s ESSO Tankvaart Mij. Site | home

Turbo-Electric Machinery for Hills Class Tankers ( Part-1 )

Zie ook / See also : Turbo-Electric Machinery for Hills Class Tankers ( Part-2 )

MARINSHIP, the shipyard near Sausalito on San Francisco Bay, has become world famous as a builder of tank-ers. This firm is nearing completion on its Maritime Commission contracts and is being converted to a marine repair plant. Recently we secured, through the courtesy of this firm, the very fine set of tanker machinery pictures that illustrate this article.

All of the tankers built at this yard are the Maritime Commission T2 - SE type, which means tanker design No. 2 with single screw and electric drive. These tankers as built at Marinship were in two divisions, the A2 or Mission class, and the A1 or Hills class. The only difference in the specifications is the horsepower of the main propulsion mach-inery, which is 10,000 shp maximum for the Mission class and 8250 shp maximum for the Hills class.

The hull design and main features were described in a Pacific Marine Review article covering the Mission class tankers of this series, and the present article is to describe and illustrate the machinery of the Hills class. Principal dimensions of these hulls are: length O.A., 523 1/2 feet; beam, 68 feet; draft loaded, 30 feet: net measurement, 6107 tons; deadweight capacity, 16,765 tons: fuel oil cargo capacity, 138,000 bbls.; normal propulsion power, 6600 shp; and cruising radius, 12,600 nautical miles.

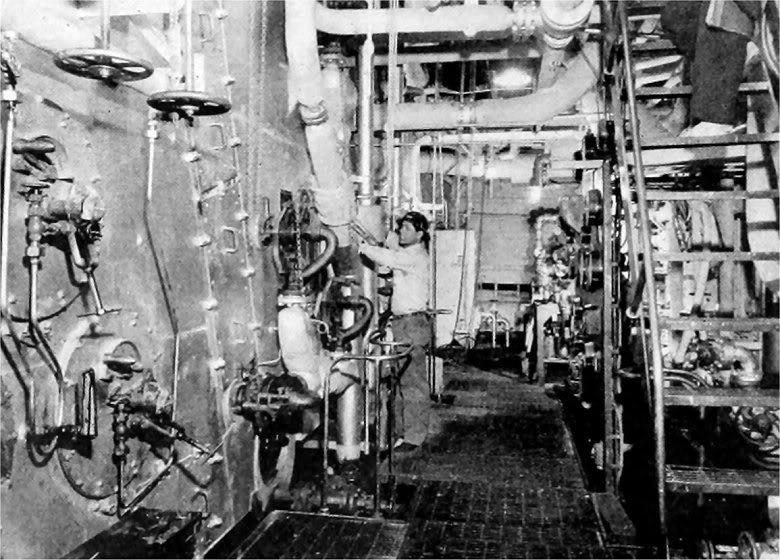

Boiler room, featuring firing front of steam generator at left and combustion control at right.

Propulsion machinery as installed on the Hills class tankers built at Marinship comprises a boiler plant generating steam for a turbo generating plant, which delivers electrical power to a large electric motor directly connected to a screw propeller through a steel shaft.

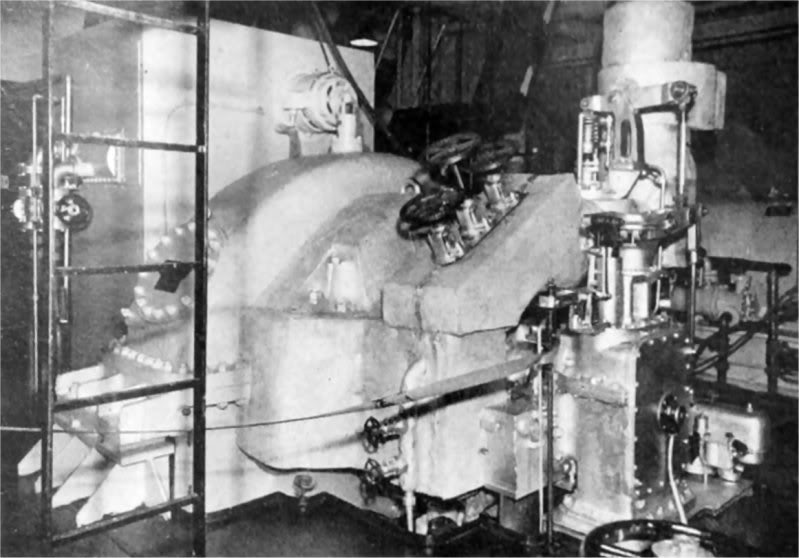

Main turbo generating set.

The steam generating plant consists of two Combustion Engineering boilers operating: 459 psi at drum; 450 psi and 730 degrees F. total temperature at superheater outlet; with a normal evaporation rate of 32,056 p.h.; and an overload capacity for 44,436 p.h.

This steam arrives at the Elliott turbine throttle with 720 degrees F. total temperature and 435 psi gage pressure and exhausts from the turbine into a Graham condenser at 28.5" vacuum. Thence the condensate is pumped through feed water heaters and Ingersoll-Rand pumps back to the boiler to repeat its cycle.

Directly connected to this turbine is an Elliott generator. At the normal speed of 3715 rpm the output in electrical energy is 5400 kw alternating current three phase 4000/2300 volts 780/1350 amperes.

Application of this electric energy to an Elliott propulsion motor produces 6600 shp on the propeller shaft at 93 rpm.

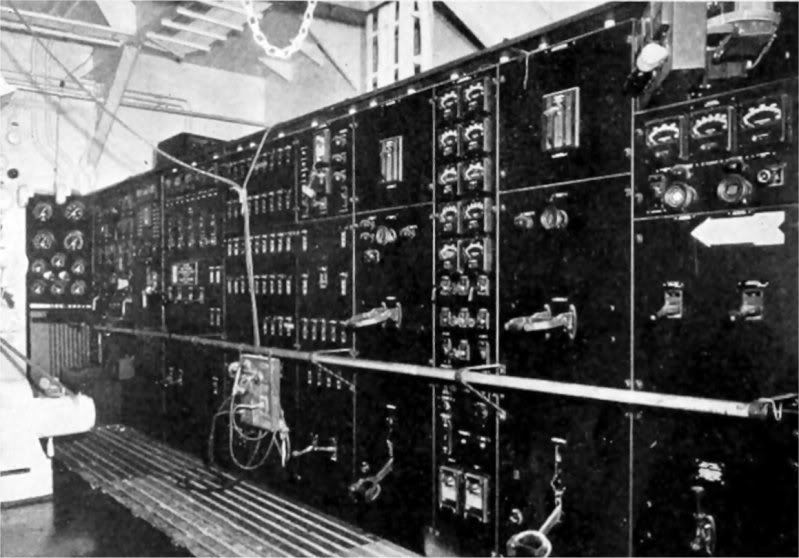

Two Elliott 400 - kw steam turbine driven generating sets are installed to take care of all auxiliary requirements. These turbines operate under the same steam conditions as do the main propulsion turbines, and the steam exhausts into a separate Graham condenser, and from thence goes into the same cycle of feed water heaters and feed pumps as the main turbine steam.

Main switchboard.

The principal auxiliary load on any tanker is the pumping of cargo.

On the Hills class T2 tankers the main cargo pumping load is taken by three 2 stage Ingersoll - Rand centrifugal pumps driven by Westinghouse electric motors. Each of these pumps has a capacity to discharge 2000 gpm against 100 psi. For stripping, two electric motor drive rotary type Ingersoll - Rand pumps are installed, each with a capacity for 400 gpm at 100 psi discharge pressure. There is also a standby steam drive Worthington reciprocating stripper 14" x 14" X 12".

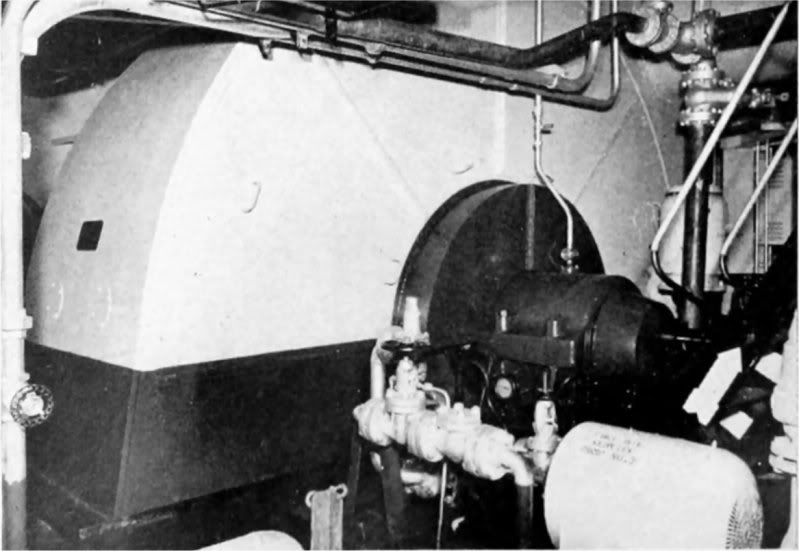

Main propulsion motor on tanker

The two main feed pumps are Ingersoll - Rand centrifugals driven by Elliott steam turbines. Each of these pumps has a capacity for 200 gpm at 575 psi discharge pressure.

Steering gear is of the hydroelectric double ram Rampson slide type with duplicate differential hydraulic pumps each driven by a 30-hp Westinghouse motor. This gear was built by Stetson-Ross.

The windlass is a product of Hesse-Ersted and is a steam drive double wildcat machine with capacity to lift two 11,400-lb. anchors at .^3 feet a minute. This firm also supphed two steam drive cargo winches each having capacity to lift 9200 lbs. at 190 ft. per minute.

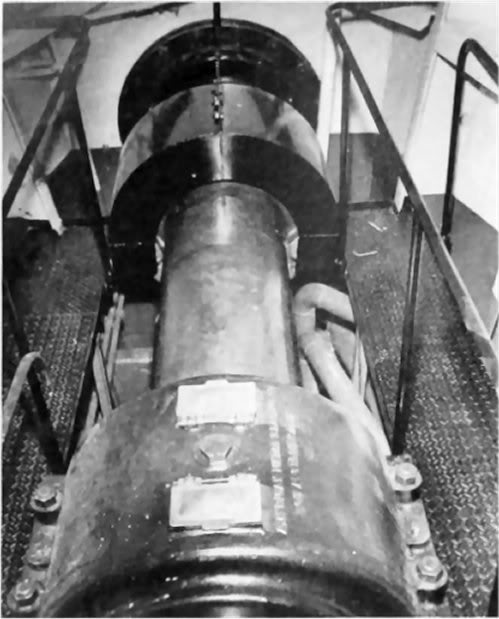

Propeller drive shaft

An American Engineering steam driven warping winch capable of exerting a rope pull of 17,500 pounds is included in the deck machinery.

Electric motor drive general service pumps include: one fire and Butterworth cleaning system; one fire and general service; two Quimby fuel oil service; two Quimby lube oil pumps; two La Boin bilge; and one Quimby fuel oil transfer. Steam drive standby pumps are one 14" x 14" X 12" fuel oil transfer, and one 10" X 7" X 10" fire and ballast, both

Worthington.

The machinery of these tankers has functioned satisfactorily even during the hectic war service in which they are all at present engaged.

Source : Pacific Marine Review, Volume 42, July 1945.

|

Zie ook / See also : Turbo-Electric Machinery for Hills Class Tankers ( Part-2 )