FSO / FPSO > 200.000 DWT | home

Fulmar FSU

( Photo Copyright Reserved )

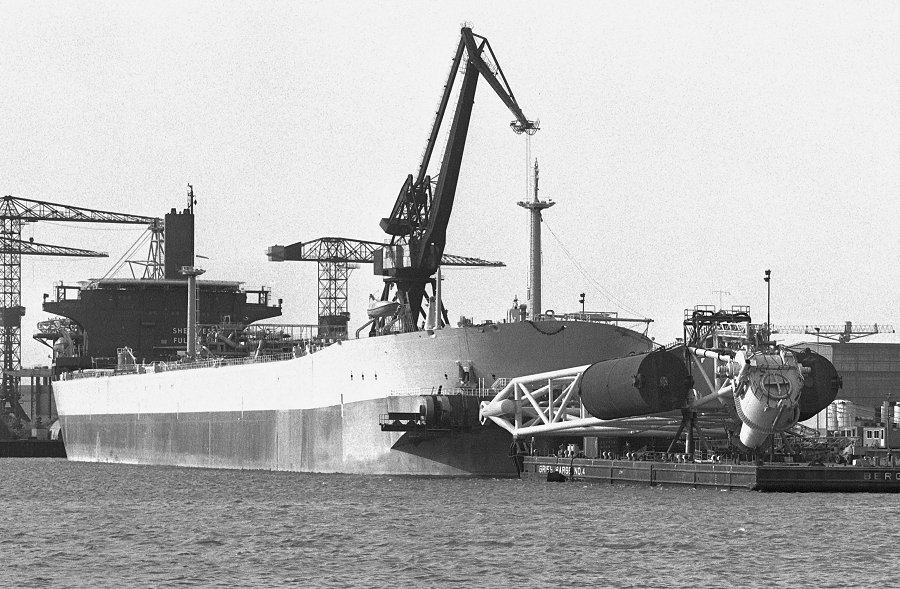

"Fulmar FSU", under construction at Rotterdam, June 1998.

( Photo Copyright Jörg Seyler )

"Fulmar FSU", under construction at Rotterdam, June 1998.

( Photo Copyright Pieter Melissen )

"Fulmar FSU", under construction at Rotterdam, June 1998.

( Photo Copyright Pieter Melissen )

"Fulmar FSU", under construction at Rotterdam, June 1998.

( Photo Copyright Jörg Seyler )

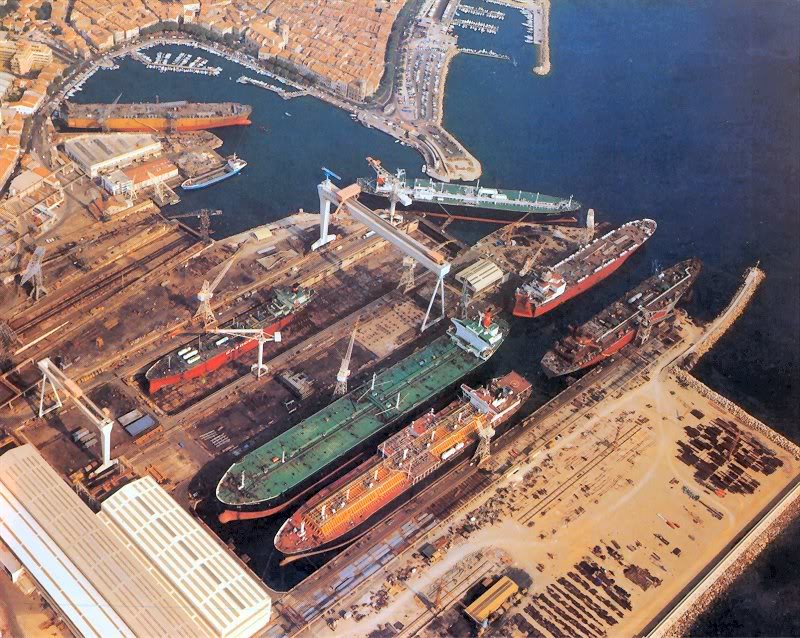

"Medora" before conversion into Floating Storage Unit “Fulmar FSU”, seen here in the middle, green deck.

( Photo Chantiers Navals De La Ciotat )

"Medora Fulmar Field Flatform "A", ex. "Medora" at Keppel, Rozenburg, Holland, for new fore-arm.

( Photo Keppel )

"Fulmar FSU", in the Northsea.

( Copyright reserved )

"Medora" after conversion into Floating Storage Unit “Fulmar FSU”.

( Photo Chantiers Navals De La Ciotat )

( Copyright Reserved )

The Fulmar Single Anchor Leg Mooring (SALM) permanently moors a converted tanker serving as a Floating Storage Unit (FSU) in the North Sea at Shell/Esso's Fulmar Field. The Fulmar storage and offloading system is the first such system installed in a rough weather area.

The installation of the SALM was unique, not by choice, but because of the requirements imposed by the nature of the system and by the environmental effects on the structure during installation. The SALM is comprised of very large, heavy structural components joined by mechanical articulations and connections. The size and weight necessitated that the connection of the FSU to the buoy be made offshore. The installation of the structure was weather sensitive, requiring the design of numerous "hold points" into the procedure; for instance, the SALM buoy acted temporarily points" into the procedure; for instance, the SALM buoy acted temporarily as a gravity structure, being transformed finally into a pile founded structure.

The loadout and installation strained the capacity of both dockside and moating equipment and produced several new world weight records. Novel applications of conventional equipment were used for loadout and transport of the components, for rigging used to make the major offshore lifts and connection between moving assemblies and for the rapid slurry installation of the permanent ballast.

This paper describes the installation procedures along with the corresponding field experience. Data on rigging, lift weights, seastate limitations and schedule are presented for use by those who may be faced with a similar opportunity.

Introduction

The Fulmar Field development plan emphasized early production. A seafloor template was set on location and several wells drilled that were tied back to a wellhead jacket set over the drilling template. A main jacket supporting the quarters, production and drilling facilities was set alongside and connected to the wellhead jacket by a bridge. The production from these first wells will generate revenue while the remaining wells are being drilled from the main platform and bring the production up to full capacity earlier in the life of the field. Production flows through a 16 inch pipeline from the platform to the storage tanker (FSU) moored to the SALM located 2.3 km (1.4 mi.) away (Figure 1). The produced oil is stored on board until it is offloaded to shuttle tankers which moor in tandem astern the FSU. The total development cost of the Fulmar Field will be approximately 580 M. The total installed cost of the SALM and FSU are 27 M and 42 M, respectively.

The installation of the Fulmar SALM buoy and base was accomplished using a large semisubmersible crane barge fitted with two revolving cranes - the "HERMOD" owned by Heerema Offshore Contractors. At one time during the design phase an alternate method of a self-floating vertical tow of the buoy and base was considered. This entailed some risk if a summer storm developed when the buoy was towed in less than the Fulmar site depth of 80 m (280 ft.). Also, because the "HERMOD" (or its sister ship, the "BALDER") was to be used on the Fulmar platform installation and a heavy lift crane was required for the attachment of the tanker to the buoy, the HERMOD was selected for the SALM installation as well.

|

( You will be directed to Helderline.nl )

|

Additional Information by Kees Helder ;

Naam

|

Name

|

Medora

|

IMO Nr.

|

IMO Nr.

|

6823090

|

Roepnr.

|

Callsign

|

GYKN

|

Bouwjaar

|

Build

|

1968

|

Werf

|

Yard

|

Mitsubishi Heavy Industries, Nagasaki, Japan.

|

Bouwnr.

|

Build. Nr.

|

1655

|

In dienst

|

In service

|

01/11/1968

|

Eigenaar

|

Owner

|

Shell Tankers UK, Londen.

|

Vlag

|

Flag

|

British

|

Thuishaven

|

Homeport

|

London

|

Type

|

Type

|

Tanker

|

Klasse

|

Class

|

LR

|

Sub Type

|

Sub Type

|

Crude

|

Lengte (o.a.)

|

Length (overall)

|

325.08 mtr.

|

Lengte (p.p.)

|

Length (p.p.)

|

- mtr.

|

Breedte

|

Beam

|

47.22 mtr.

|

Holte

|

Depth

|

28,43 mtr.

|

Diepgang

|

Draft

|

18.95 mtr.

|

Tonnage DWT

|

DWT

|

210.658 ton

|

Tonnage GT

|

GT

|

105.252 ton

|

Tonnage NT

|

NT

|

74.999 ton

|

Inhoud

|

Cubic

|

- m3

|

Machine(s)

|

Engine(s)

|

2 Mitsubishi steamturbines.

|

Vermogen

|

Output

|

28.000 Hp

|

Snelheid

|

Speed

|

15.0 mile

|

Verbruik

|

Consumption

|

- t/h

|

Aantal Tanks

|

Total Tanks

|

8 centertanks and 5 wingtanks from which 2 Clean ballast tanks.

|

Bijzonderheden

|

Remarks

|

Total 22 M-class tankers for Shell Tankers where build.

|

Historie

|

History

|

|

Status

|

Status

|

1979 Sold and rebuild as a Floating Storage Unit “Fulmar FSU”.

|

Original Name

|

Medora

|

Type

|

VLCC

|

Delivered

|

29-11-1968

|

IMO No

|

6823090

|

Builder & Yard

|

Mitsubishi Heavy Ind., Ltd., Nagasaki, Japan

|

Yard No

|

1655

|

Engine

|

Steam

|

KW

|

20888

|

GRT

|

105252

|

NTR

|

74999

|

DWT

|

210658

|

LOA

|

325,03

|

LBP

|

310,02

|

Beam

|

47,22

|

Draft

|

18,96

|

Depth

|

24,52

|

Other names and history

|

1981 Fulmar F.S.U. rebuild as FPSO

1996 SPU 4

1998 Red Fulmar I

2002 Scrapped in China

|

Code

|

FPS

|

Scrapped

|

01-10-2002

|

The Miramar Ship Index for "MEDORA"

IDNo:

|

6823090

|

Year:

|

1968

|

Name:

|

MEDORA

|

Keel:

|

01.04.1968

|

Type:

|

Tanker

|

Launch Date:

|

21.07.1968

|

Flag:

|

GBR

|

Date of completion:

|

29.11.1968

|

Tons:

|

105252

|

Link:

|

-

|

DWT:

|

210658

|

Yard No:

|

1655

|

Length overall:

|

325.0

|

Ship Design:

|

|

LPP:

|

310.0

|

Country of build:

|

JPN

|

Beam:

|

47.2

|

Builder:

|

Mitsubishi

|

Material of build:

|

Location of yard:

|

Nagasaki

|

|

Number of screws/Mchy/Speed(kn):

|

1ST-16

|

||

Subsequent History:

1981 dump hulk - 1981 FULMAR FSU - 1996 SPU 4 - 1998 RED FULMAR I

Disposal Data:

Converted to a non-propelled offshore oil installation 1981, & scrapped 01.10.2002.

History:

ON

|

LR/IMO

|

ID

|

Year

|

Name

|

Tons

|

Change

|

Registered Owner

|

336950

|

6823090

|

6823090

|

1968

|

MEDORA

|

105252

|

-

|

Shell Tankers (UK) Ltd.

|

6823090

|

6823090

|

1968

|

FULMAR FSU

|

105252

|

1981

|

Shell Exploration and Prod. (Shell Expro)

|

|

6823090

|

6823090

|

1968

|

SPU 4

|

105252

|

1996

|

?????

|

|

6823090

|

6823090

|

1968

|

RED FULMAR I

|

105252

|

1998

|

?????

|