BULK- & ORE Carriers >175.000 DWT Part S - Z | home

Vale Brasil

See also : 2 video-films Vale Brasil

"Vale Brasil".

( Copyright reserved )

"Vale Brasil".

( Copyright reserved )

"Vale Brasil".

( Copyright reserved )

"Vale Brasil".

( Copyright reserved )

"Vale Brasil". Arriving at Rio de Janeiro, March 2012.

( Photo Copyright Edson de Lima Lucas )

"Vale Brasil". Anchored at Guanabara Bay/Rio de Janeiro., March 2012.

( Photo Copyright Edson de Lima Lucas )

"Vale Brasil".

( Copyright reserved )

"Vale Brasil". Sternview.

( Copyright reserved )

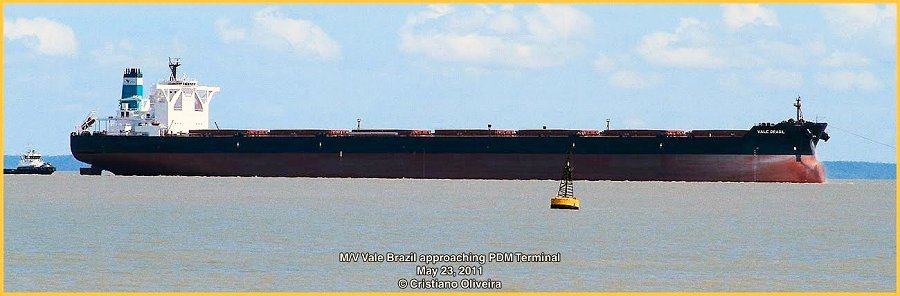

"Vale Brasil", approching terminal, May 23, 2011.

( Photo Copyright Cristiano Oliveira )

DSME Delivering Vale Brasil, the worlds largest Ore Carrier.

The Vale Brasil, the first 400K ore carrier to be delivered to Vale, Brazil’s giant mining company, was successfully delivered by DSME in March 2011. DSME is to build a series of seven vessels, each 362 metres long, 65 metres wide and with a loading capacity of 400,000 deadweight tonnes.

Vale’s 400K ore carriers are being constructed by Daewoo Shipbuilding & Marine Engineering (DSME), Korea and Jiangsu Rongsheng Heavy Industries, China. So far the largest ore carriers ever built, the economies of scale of these new VLOCs will make transporting iron ore cheaper and more fuel efficient.

DSME, one of the world’s leading shipbuilders, already has experience of building large-size ore carriers with such loading capacity. The size itself was not a problem for DSME, but several critical concerns, such as the waveinduced vibrations, had to be considered right from the initial engineering stage. Vale’s particular concern about how these wave-induced vibrations might affect its new build VLOCs led DSME and DNV to take this effect into account in the initial design, based on the actual dedicated trade route.

Safety concerns addressed through advanced fatigue assessment

The Vale Brasil required the most advanced procedure for directly calculating fatigue assessment, based on DNV’s CSA-2 notation. The advanced calculations ensure that all critical structures are adequately designed to meet specified fatigue and strength requirements, taking into consideration the greatly increased vessel size, operation in the dedicated environment and potential uncertainties.

“DSME tested the effect of springing and whipping – i.e. of wave-induced vibrations - on the fatigue life over a 30-year lifetime on the Brazil to China route. We’ve been able to apply hull-girder-induced fatigue based on the actual model test results for springing and whipping. In applying DNV’s CSA-2 notation, DSME utilised its DSTAS and DSFAS calculation modules, which helped to make the whole engineering process easier,” says Mr Lee, DongKwon, a DSME structural engineer.

For each calculation, DNV verified the whole process based on its accumulated experience from similar vessels to ensure that the correct factors had been used and minimise the effect of uncertainties. “The engineering for the Vale Brasil was a demanding process since additional advanced calculations had to be carried out to ensure that structural details were adequately designed based on the direct calculation of load and response, including potential uncertainties for the actual trade route. Especially since the design period was two months shorter than for other conventional commercial ships, DNV’s advanced engineering know-how and experience were essential factors that expedited the whole process,” adds Mr Lee.

Solution to increase the loading efficiency

The Vale Brasil ensured loading efficiency by applying EL-2, DNV’s efficient loading notation. DNV’s EL-2 notation allows easier and more flexible loading sequences, ensuring safe and more efficient loading for this specialised ore carrier by allowing each cargo hold to be completely filled in one pass at a high loading rate without compromising the strength and fatigue life of the vessel. VLOCs with EL-2 will have a documented high loading rate with a significantly reduced loading time, which was a must for Vale.

“In order to apply EL-2, the envisaged operating and loading patterns needs to be fixed at the initial design stage. Sufficient hull girder and local structural strength are prerequisites for safely accommodating a one-pour loading. In addition, the capacity of the ballast pumps and appropriate size of the main ballast lines, including the separate stripping system, are key to the loading and operating flexibility. All these key components were closely taken into account by the yard, DSME, from the early design stage in order to maximise the benefit of this notation,” says Mr Lee, Hwa Lyong, the Project Director at DNV’s Approval Centre in Korea who supervised the whole Vale Brasil approval process.

The EL-2 notation has been applied to all Vale’s series of ore carriers built by DSME and also to the VLOCs cur-rently under construction at the Jiangsu Rongsheng shipyard in China.

DNV currently has 10 VLOCs under way in Korean yards, including DSME, 24 being built in China and five in Japan, representing 40% of the ships of this type on order.

|

Vessel information :

IMO number :

|

9488918

|

|

Name of ship :

|

VALE BRASIL

|

(since 01-03-2011)

|

Call Sign :

|

9V9127

|

|

MMSI :

|

564905000

|

|

Gross tonnage :

|

198980

|

(since 01-03-2011)

|

DWT :

|

402347

|

|

Type of ship :

|

Ore Carrier

|

(since 01-03-2011)

|

Year of build :

|

2011

|

|

Flag :

|

Singapore

|

(since 01-03-2011)

|

Status of ship :

|

In Service/Commission

|

(since 30-03-2011)

|

Name: Vale Brasil

IMO No: 9488918

Built: 03/2011

Ex: Ore China-2011

Type: Ore Carrier

Status: In service

SubType: Ore

Flag: Singapore

DWT: 402,347

Draft: 22.00

Builder: Daewoo Shipbuilding & Marine Engineering Co., Ltd. (1201)

GT: 198,980

LOA: 362.00/350.00

Owner: Vale Shipping Holding Pte. Ltd.

NT: 67,993

Beam: 65.00

Speed/Cons: -/-

Class: NV

Depth: 30.40

Engine Type: Diesel engine, ?? kW

Liquid: -

Grain:-